In the recently published ‘ Stabilization of Electrospun Nanofiber Mats Used for Filters by 3D Printing ,’ international researchers explore the technology of electrospinning in detail, attempting to refine production of nanofiber mats used in applications requiring large areas of material like medical wound dressing, biotechnological procedures, and catalyzers.

.

Nanofiber mats may require added stability, often possible through the following:

.

Heat pressing

Ultrasonic welding of several other mats

Coating of mats

Laminating

Crosslinking fibers

Embedding nanofiber mats into textile composites

.

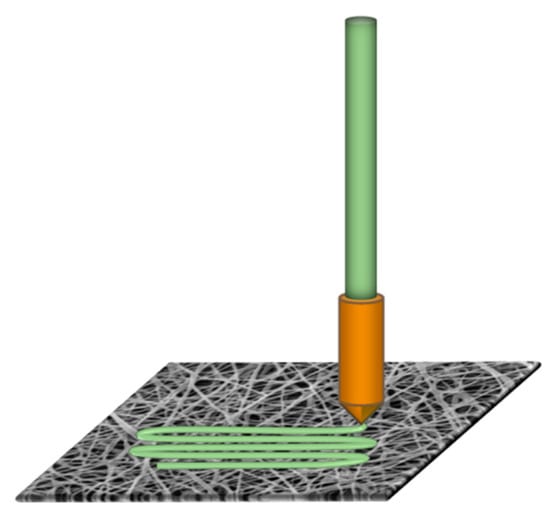

As the study of mechanical properties and improvement thereof continues to be a central focus in 3D printing, research like this also targets better ways to increase stability. For this study, samples were evaluated on a simple Orcabot XXL FDM 3D printer , using PLA as the material. 3D printing with fused deposition modeling (FDM) technology on a polyacrylonitrile (PAN) nanofiber mat. The printing polymer PLA (here green) is […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments