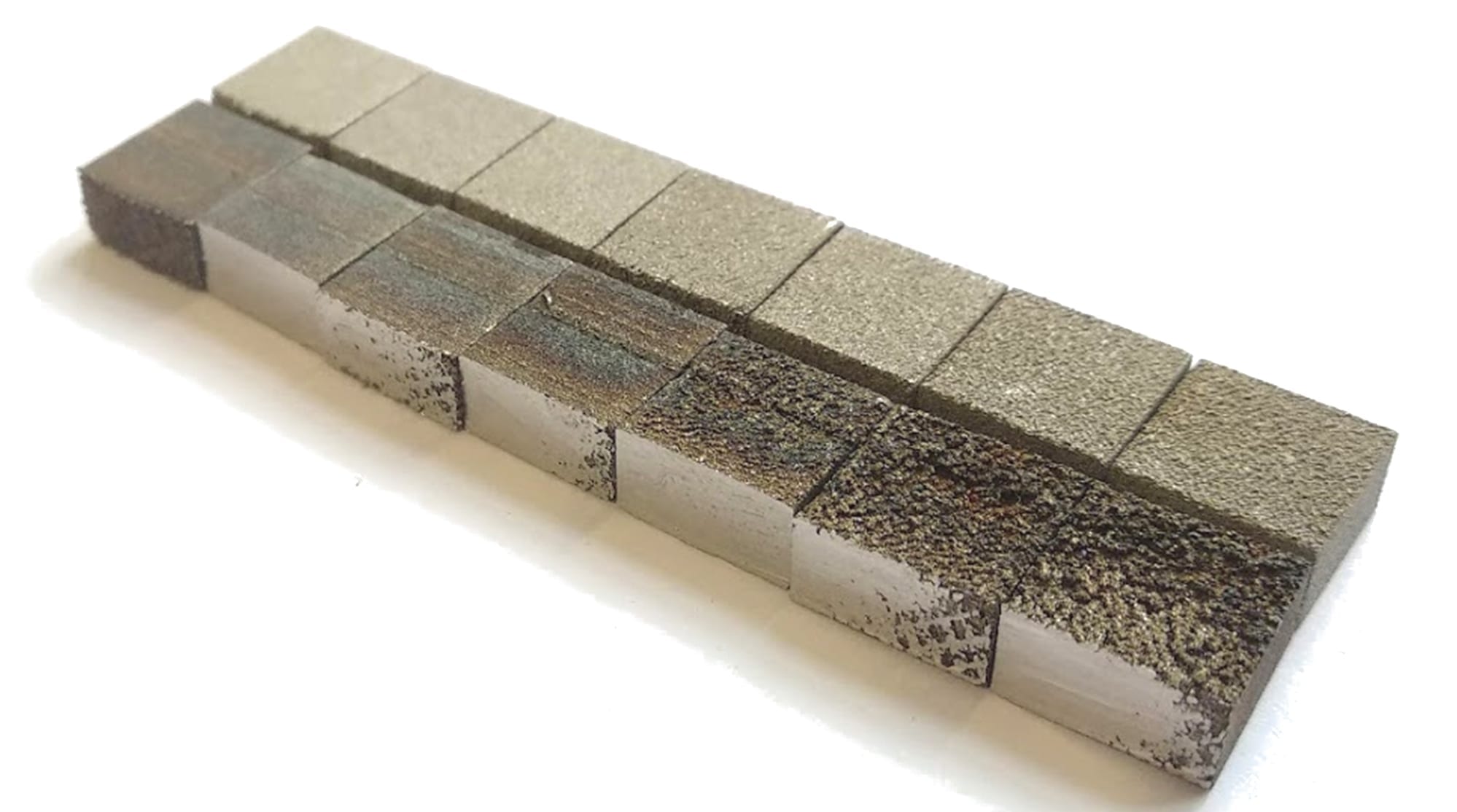

Researchers in Austria have developed a steel powder that allows even complex components to be fabricated using 3D printing, providing more design freedom without compromising the stability of the finished products.

A team led by Mateusz Skalon, a professor in the TU Graz Institute of Materials Science, Joining and Forming, developed the powder—called NewGEN SLM powder–which eliminates the need for support structures that are typically found in metal 3D-printed parts, making them more expensive to design.

Materialise Introduces 100% Reused Powder with New 3-D Printing Service

Materialise Manufacturing, a leader in 3-D printing solutions with U.S. operations based in Plymouth Township, has...

0 Comments