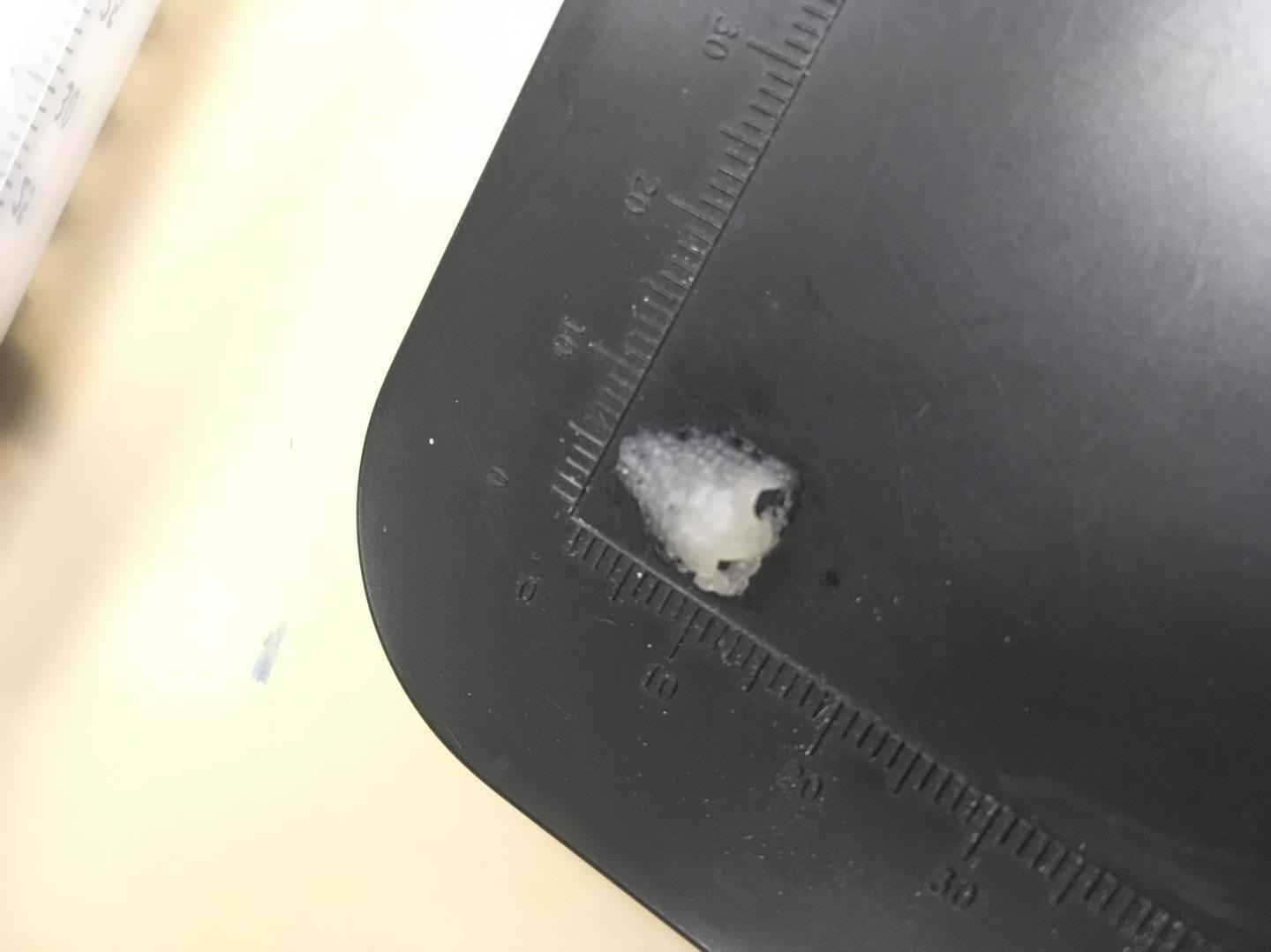

ABy mimicking the properties of human tissue, researchers have been able to create a scaffold for engineered tissues that could revolutionize medicine. The field of tissue replacement has improved significantly over the past few years with the development of impressive 3D printing techniques that can be used to help patients recover from disease or injury.

.

Scientists can now print complex, porous and personalized structures. The hope is that this can one day be extended to allow doctors and medical teams to print customized tissues in-situ for individual patients’ needs. Unfortunately, this process isn’t yet perfect. Nature is incredibly complex and mimicking it is no easy task.

.

One of the challenges facing bioengineers is that real tissues like skin grow on ‘scaffolds’ of tissues that have similar properties to themselves. This means that muscle cells successfully grow on scaffolds that feel like muscles, whilst skin ‘prefers’ to develop on skin-like scaffolds. Professor Arda Gozen and his team could have hit upon a solution to this challenge, however. Together with a team of researchers including Joan Berry and George Berry, associate professors in the School of Mechanical and Materials Engineering, Washington State […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments