To say that additive manufacturing is a growing industry is an understatement. The industry is expected to grow to $35 billion by 2027.

.

Already, advances in technology have reduced the size and cost of key additive components and the industry is on track for 14 percent growth year over year. Government support of additive manufacturing is also on the rise as agencies leverage this layer-by-layer approach to reduce turnaround times, improve operations and shore up supply chain security.

.

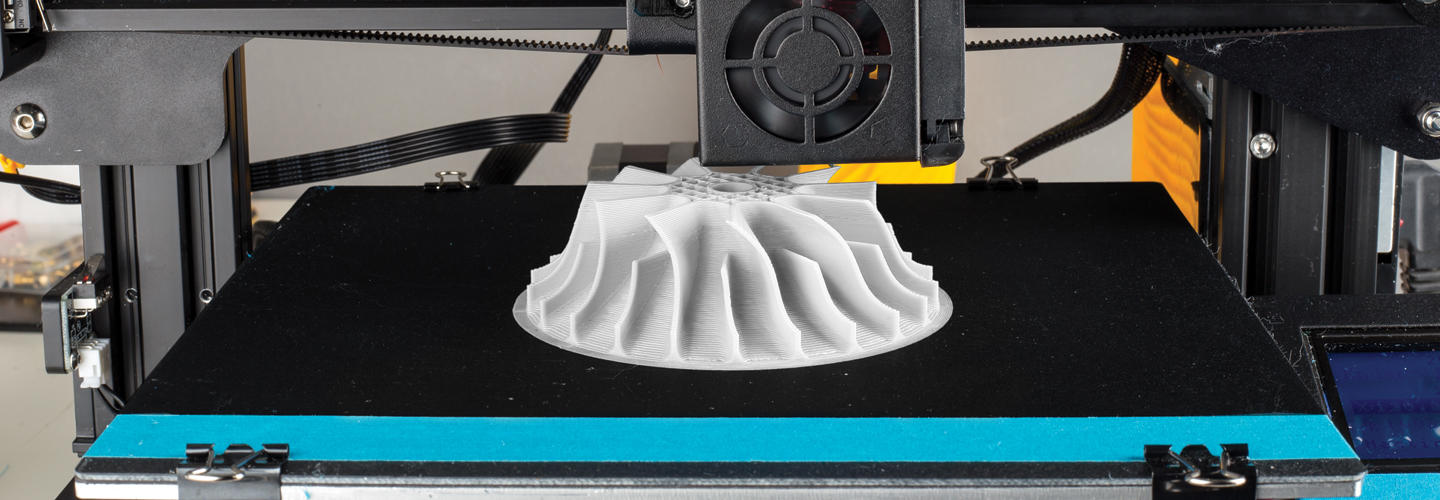

What Is Additive Manufacturing? Additive manufacturing, often known as 3D printing, is helping federal agencies build better, faster and smarter. Additive manufacturing leverages computer-aided design (CAD) software or integrated object scanners to create digital images of desired parts or products. Connected printing hardware then builds the desired object, layer by layer, effectively “adding” material bit by bit to create the finished product. Traditional manufacturing, meanwhile, uses the opposite approach — material is removed via processes like carving, machining or milling to produce the end result. This creates a twofold concern: Some material is inevitably wasted during the process, and the output object isn’t fully optimized. Consider a car door. Traditional manufacturing processes have largely automated the creation of these parts: Component […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments