Emmanuel Segura-Cárdenas ( Tecnologico de Monterrey, Escuela de Ingenieria y Ciencias ) and Luis Fernando Velásquez-García ( MIT ) detail the results of a recent study in ‘ Additively Manufactured Robust Microfluidics via Silver Clay Extrusion ,’ explaining how they created a proof-of-concept microfluidic capable of decomposing hydrogen peroxide.

.

While most microfluidics are composed of silicone, such materials are incapable of handling high temperature or pressure—and they are not very compatible with solvents. Metal could be considered a suitable choice for the development of sturdy microfluidic devices, but currently, most of that technology is geared toward the creation of thin films and wafer bonding.

.

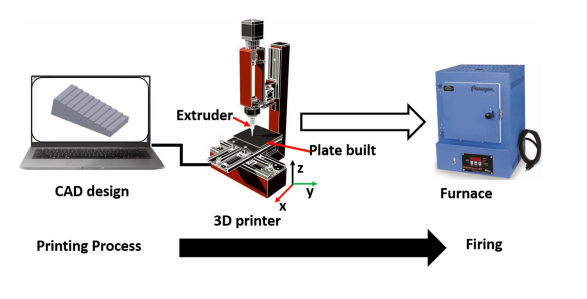

“In addition, fabrication approaches such as electric discharge micromachining [9] and micro milling [10] have been explored to implement metal microfluidics, but these manufacturing processes are very expensive, very slow, and require specialized tooling.” Schematic of 3D printing process to create metal clay-extruded objects Today, […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments