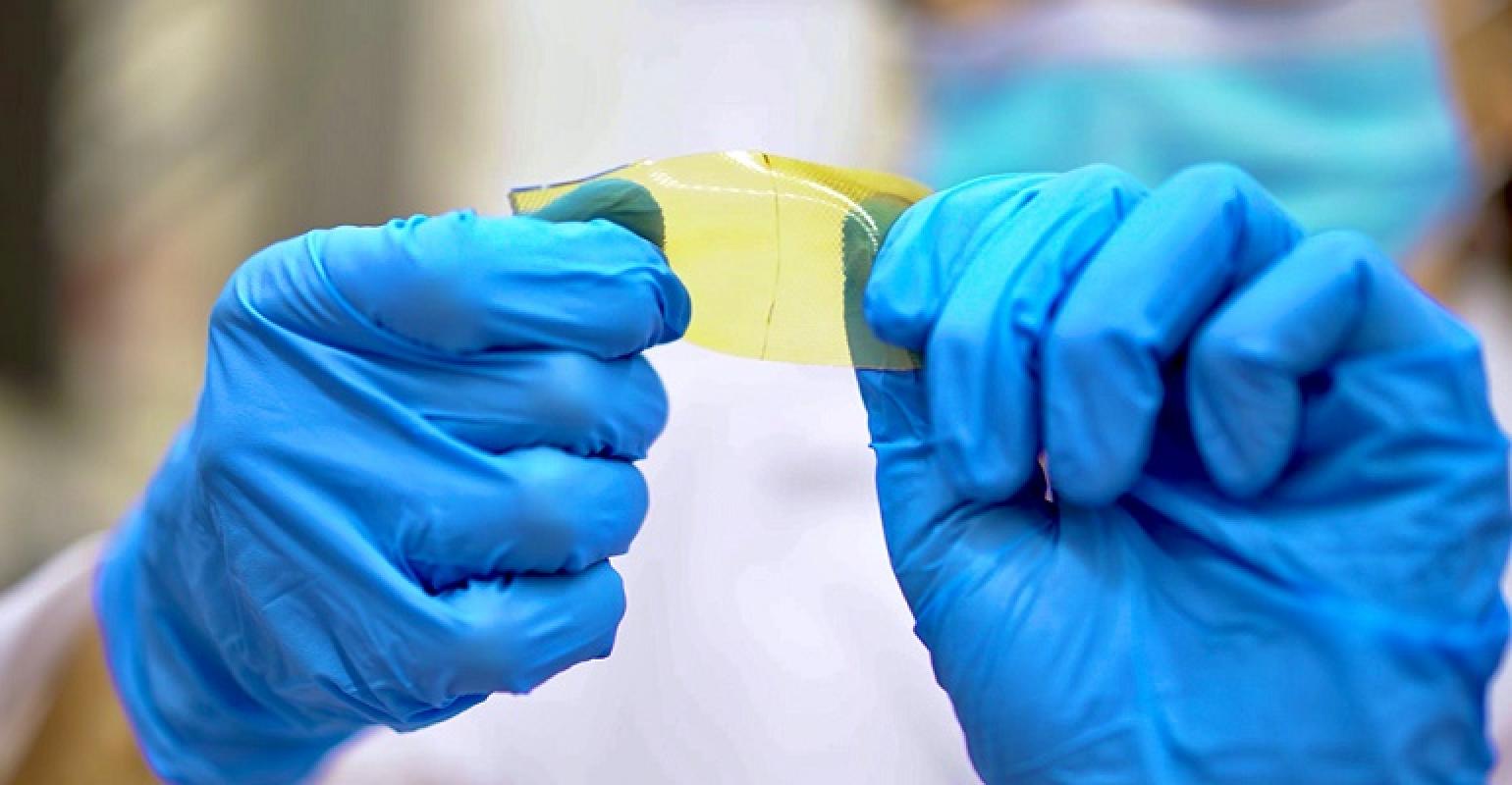

Researchers have developed a new family of self-healing polymers they believe can help in the production of more realistic, human-like prosthetics.

.

A team at Texas A&M University, working with the U.S. Army Combat Capabilities Development Command Army Research Laboratory, tweaked the chemistry of a single polymer to develop the new materials, which are 3D printable, self-healing, and recyclable.

.

The materials also come in a range of textures, from extremely soft to rigid, as well as naturally adhere to each other in air or even underwater. This combination of features is what makes the new polymer family well-suited for a variety of applications, such as developing more realistic prosthetics and soft robotics that not only have more flexibility but also can self-heal, said Svetlana Sukhishvili, a professor in the Department of Materials Science and Engineering.

.

They also have the potential for military applications, which is one of the reasons the Army collaborated on the research. Some uses the Army is eyeing for the materials are agile platforms for air vehicles as well as more futuristic designs, such as aircraft wings that can self-heal. .

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments