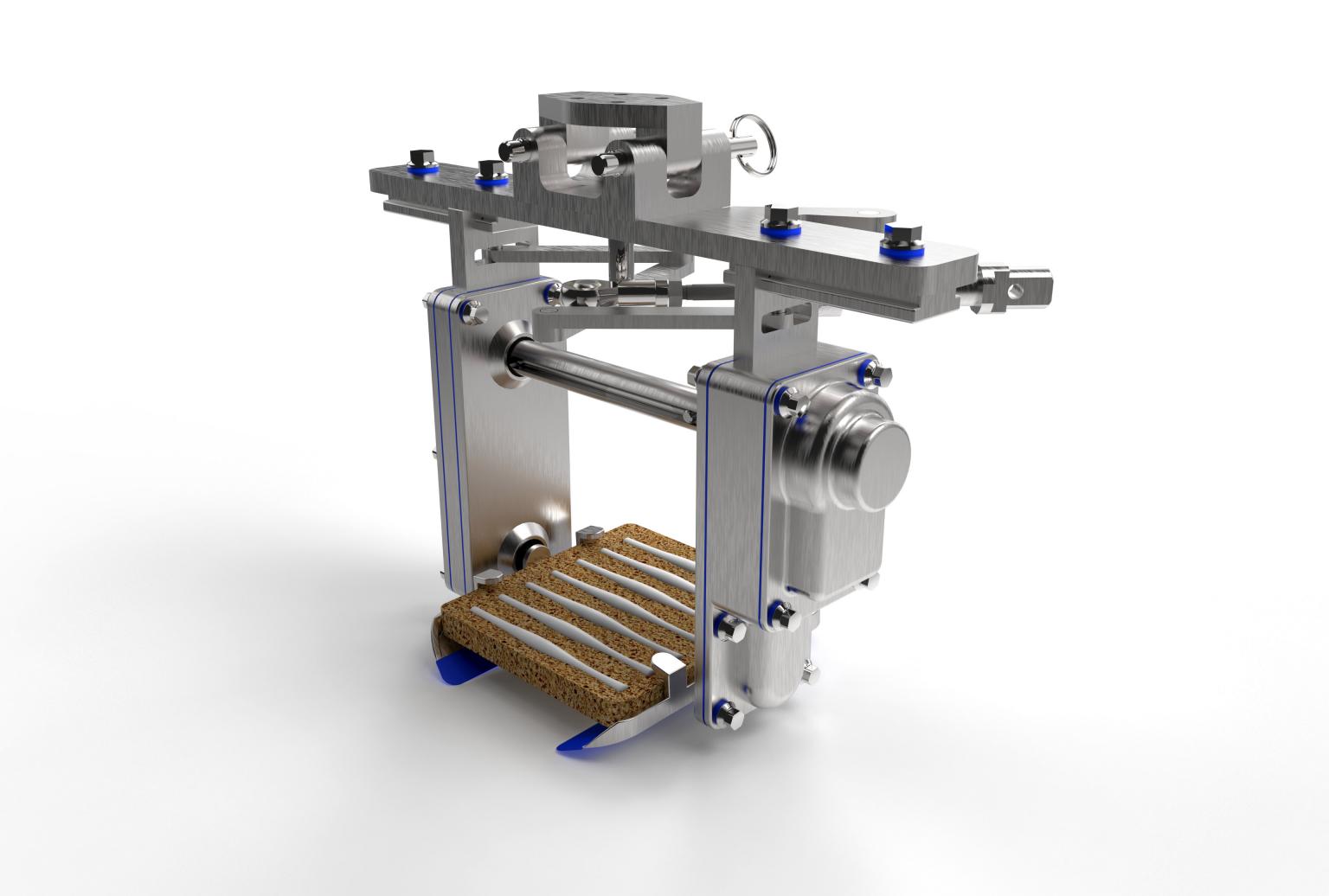

The lidding prototype Improving automation through additive manufacturing Active8 Robots specialises in the smarter application of robotics technologies, industrial automation and system integration solutions. A repetitive dexterous task, such as grabbing, lifting, picking or positioning is considered simple and easy for an able-bodied human but is often too complicated and involved for a robot to achieve by itself.

.

Active8 Robots has considerable expertise in designing and developing solutions to overcome such challenges. With a rapid prototyping capability that can go from paper to prototype in 24 hours, the company has provided countless iterations for bespoke end-of-arm tooling and adaptations to existing industrial robots and cobots.

.

Having worked with independent additive manufacturing solutions provider Creat3D over the past five years, Active8 Robots has developed a dedicated innovation centre, whereby additive manufacturing (AM) has become an integral part of its portfolio. A particular focus has been delivering bespoke 3D printed end-use components for highly intricate tasks. These 3D printed parts have enhanced functionality, are more lightweight, have lower costs and are designed, developed, tested and produced faster than traditionally manufactured parts. The applications Clients approach Active8 Robots with a wide variety of needs and objectives for […]

Click here to view original web page at www.engineerlive.com

0 Comments