In part one of this series, we gave an overview of how 3D printing is used to fabricate molds and dies for injection molding and die casting.

.

In particular, additive manufacturing (AM) can be more cost effective for small batches of parts; however, in some cases, the technology can provide some benefits that are unique to 3D printing, regardless of batch size.

.

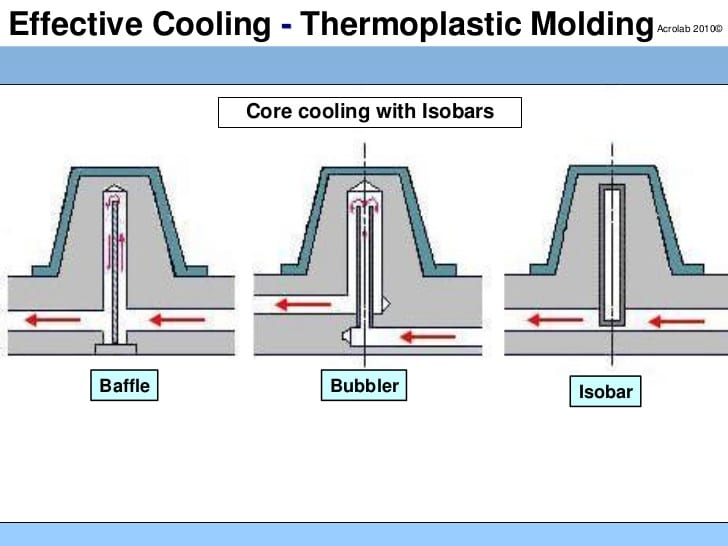

This is particularly true of 3D-printed metal molds and dies that can survive much longer than plastic molds discussed in part one. The biggest benefit that 3D-printed molds and dies offer, regardless of batch size, is the ability to integrate conformal cooling channels (air passages that follow the shape of the mold/die cavity and core) that would be impossible with traditional technologies.

.

Channels are integrated into molds and dies so that they dissipate heat more quickly, reducing the cooling time needed for the part and the tool. […]

Texas Prototype is a full-service concept to production service company offering concept review, design consultancy, material selection, prototyping, and low volume production.

.

A division of Texas Injection Molding, we understand the requirements of high-volume manufacturing and offer design for manufacturing experience to ensure cost-effective manufacturable products as product designs are delivered from prototype to high volume production.

0 Comments