In the recent ‘Numerical prediction of distortion. Benchmarking of Additive Works Amphion against real AM component,’ authors Nils Keller and Michal Prugarewicz explore how far metal 3D printing has come.

.

Looking back on a project in 2015, the authors explain that the first pre-serial, completely 3D printed gas turbine part was fabricated and released. Meant for commercial use, manufacturing of this part also meant validation of AM powder technology for an industrial gas turbine.

.

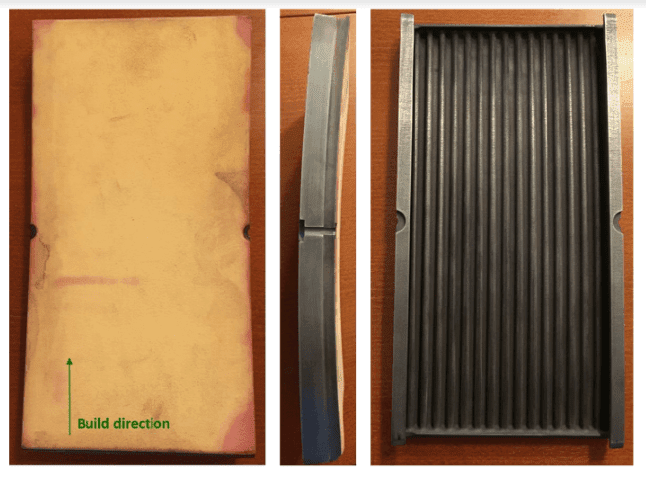

Researchers continued to work on the design, and it evolved over time—so far as to be installed in machinery for a customer; however, issues with distortion continued to be a problem and project managers realized a solution would be required for ultimate success in production. What was needed was a method for controlling distortion while engineers were involved in the build process. Ex-service component While an application with a nickel-based superalloy Inconel IN738 was considered […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments