Metal-organic frameworks (MOFs) rank among the best materials for catalysis, gas storage and gas storage and processing. So far, more than 20 000 different MOFs have been fabricated and characterized.

.

“While MOFs are produced as loose powders and tested as such at the laboratory scale, applications generally require easy-to-handle solids with a specific shape and sufficient mechanical robustness to withstand long-term damaging stresses, such as attrition and hydrostatic pressure,” Jérémy Dhainaut, a researcher at the Unité de Catalyse et Chimie du Solide (UCCS), Université de Lille (he was a post-doctoral researcher at the Institute for Integrated Cell-Material Sciences (WPI-iCeMS) at Kyoto University at the time of this work).

.

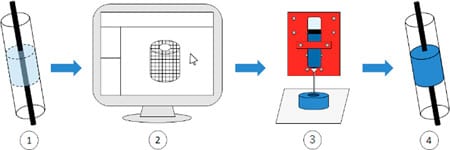

“In our recent work, we focused on the preparation of MOF-based solids by robocasting with a controlled macroscale morphology and superior textural properties.” A crucial issue for designing MOF-based solids is about finding the best comprise between […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments