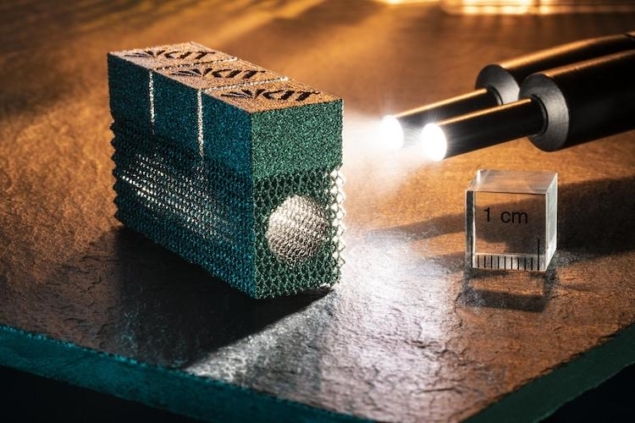

Markus Breig, KIT Tungsten has many excellent properties. It resists corrosion, and its melting point of 3422 °C is the highest of all metals, making it an ideal material for components that operate at extreme temperatures.

.

There is a problem, though: it is highly brittle at room temperature, which means it is hard to process using conventional techniques.

.

Researchers at the Karlsruhe Institute of Technology (KIT) in Germany have now addressed this problem by adapting an additive manufacturing technique called electron beam melting (EBM) for use in tungsten processing. The resulting crack-free metal could be used in high-temperature components such as rocket nozzles, heating elements for furnaces, or parts for fusion reactors and medical imaging systems.

.

Additive manufacture The KIT researchers, led by Steffen Antusch from the Institute for Applied Materials – Materials Science and Engineering (IAM-WK) , have studied several ways of using additive manufacturing (also known as 3D printing) to make tungsten components that require little to no post-production processing. In their latest work, they used EBM to reduce strain in tungsten during processing and thus produce a soft material with no cracks that is easier […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments