Researchers from Australia and Germany are exploring more about improving 3D printed parts in the recently published ‘ Fracture Resistance Analysis of 3D Printed Polymers .’

.

Because failure—sometimes ‘catastrophic’—often occurs due to instability and cracking, the authors experimented with samples fabricated via both fused deposition modeling (FDM) and multi-jet fusion (MJF) to understand more about load-carrying capacity.

.

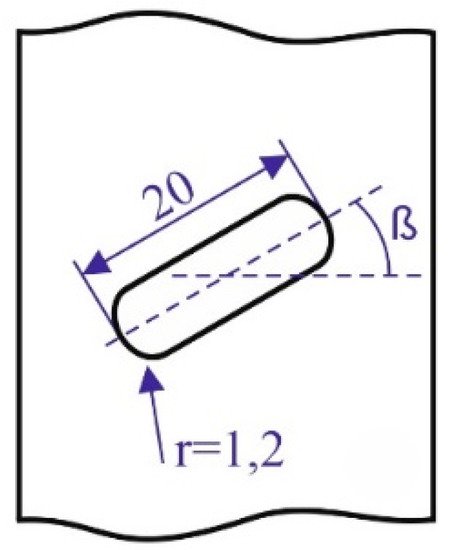

Overall, FDM 3D printing shows great potential for improving mechanical properties in 3D printing. This is an ongoing topic of study in many research labs today too, spanning many different techniques and use of materials, from studying the effects of color with PLA , to using additives , to examining mechanical properties and biocompatibility . In some cases with FDM 3D printing, however, users may experience issues with composites that have pre-existing cracks—caused during manufacturing, surface defects, or notches that may be growing slowly. In this study, the research team analyzed fracture […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments