Most medicines these days are made with mass manufacturing production methods, which produce drug forms that have identical characteristics, such as appearance, drug release, and dosage. But issues abound with this way of doing things – inappropriate dosing can cause bad side effects, and even lead to a lack of treatment for young and elderly patients.

.

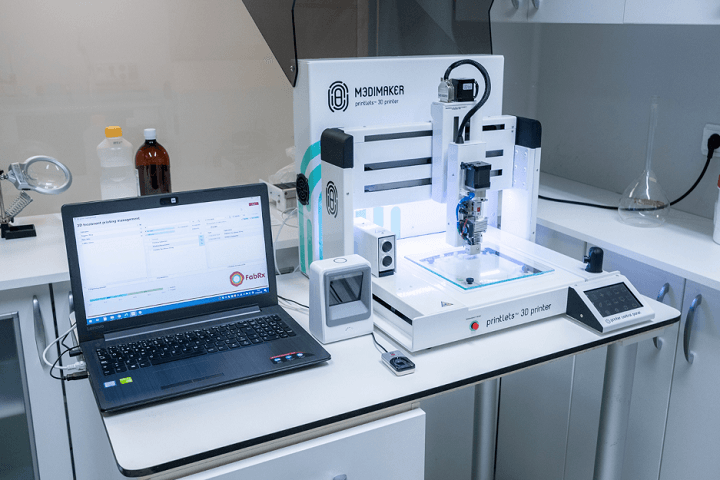

Often in pediatric treatment, caregivers are told to split, or even crush, pills in order to meet the proper dosage requirements for their age. This can actually cause inaccurate dosages, and even medicines being incorrectly used. We obviously need age-appropriate pharmaceutical formulations, but personalized medicines aren’t really in the wheelhouse of most traditional manufacturing methods. Founded in 2014, FabRx Ltd. , a pharmaceutical biotechnology spin-out company from the University College London’s School of Pharmacy, has spent the last several years researching and developing 3D printed, customized drugs and drug-loaded medical devices . The […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments