Oliver Dietze & University of Saarland Researchers from the Saarland University have developed a novel non-contact method of transforming 3D printed metal parts into high-precision technical components for specialist applications.

.

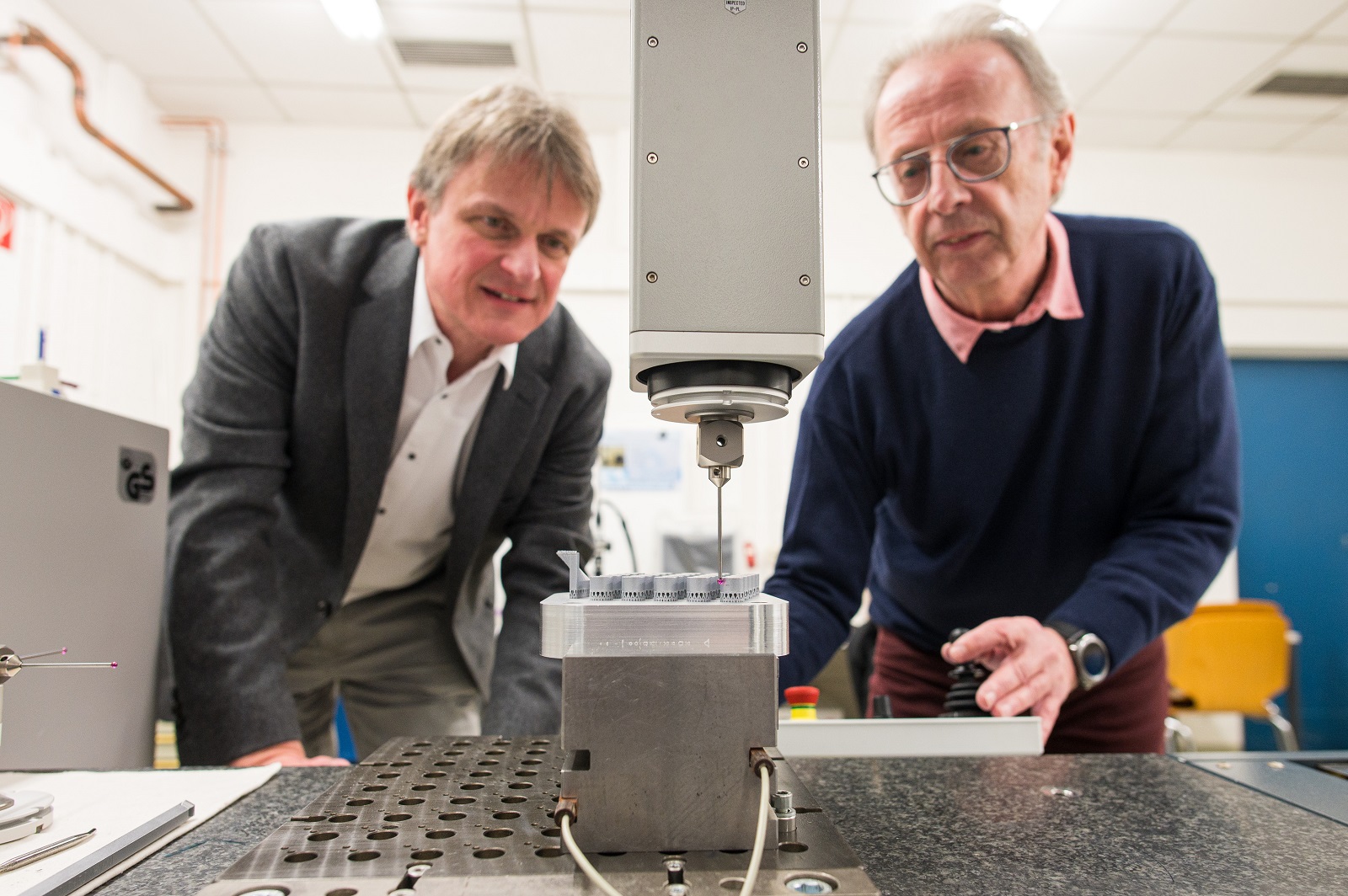

The research team consisting of manufacturing technologists combine metal 3D Printing and Electrochemical Machining (ECM). This method allows processing of strong and lightweight metal parts to produce precision-finished components with complex geometries and dimensional tolerances of a few thousandths of a millimetre. NEED FOR THE NOVEL METHOD Above: (from left to right) Researcher Shiqi Fang, technical assistant Stefan Wilhelm and team lead Professor Dirk Bähre showcasing the machined 3D printed metal parts/Image Credit: Oliver Dietze & University of Saarland The aim of the research, led by Professor Dirk Bähre, was to develop a highly […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments