After reading the now famous article about a ventilator valve that can be 3D printed for $1, compared to the traditionally-manufactured valve costing $11,000, I realized that the way 3D printing costs are calculated is still vastly oversimplified, which leads to reliance on two incomplete cost models.

.

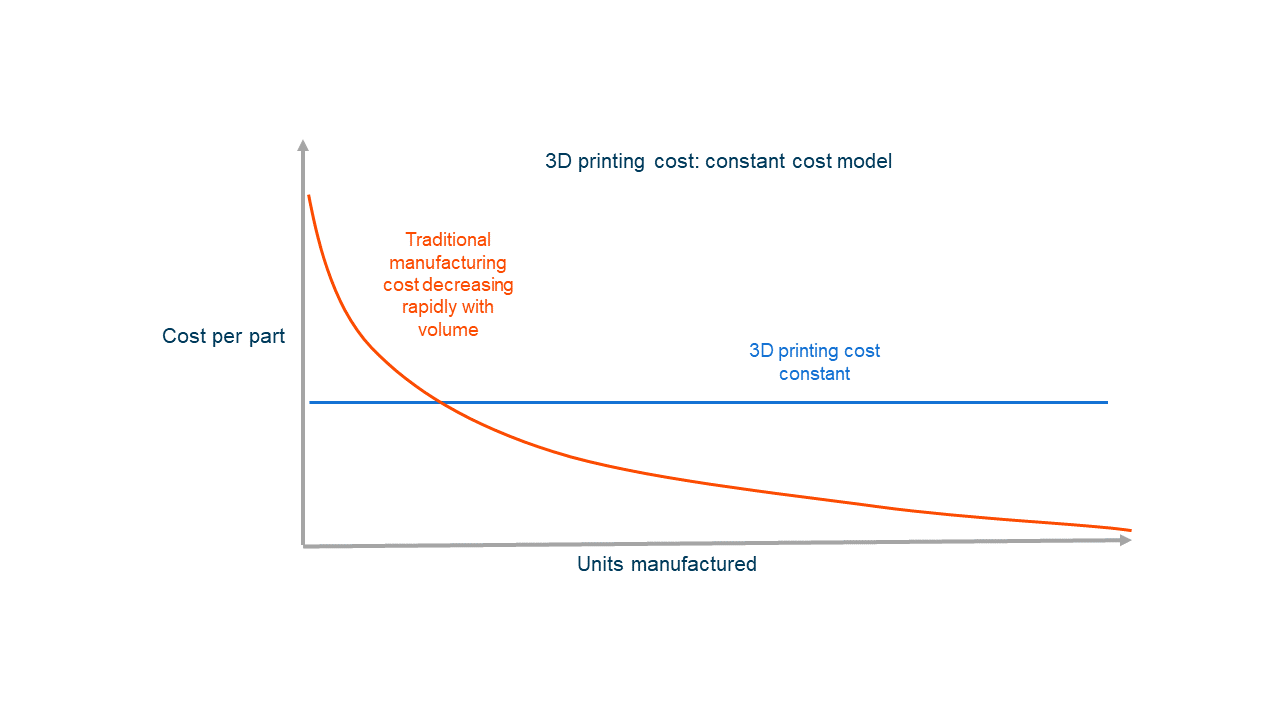

The most common says that unlike traditional manufacturing there are never economies of scale and that the cost per part stays constant, whether a single part or 100s of parts are printed. Another model is that 3D printing costs slightly decrease with the number of units as more parts are added to the build bed, and the average build time per part decreases.

.

Both of the above models provide a cost approximation and are often used by service bureaus, but they both have the same flaw: They don’t take the machine utilization into account. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments