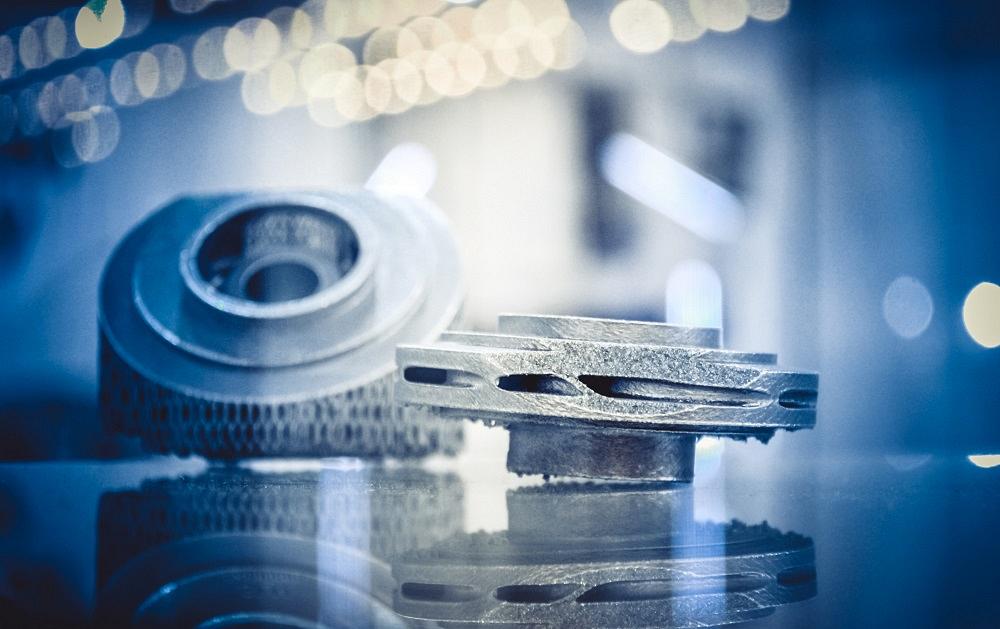

Metal additive manufacturing has come a long way. Now even extremely large parts are being fabricated layer by layer.

.

Metal fabrication is largely subtractive in nature. In processes like cutting, grinding, and drilling, a portion of the base material becomes scrap, requiring systems for scrap handling, disposal, and perhaps recycling. Some “additive” processes like casting and molding have existed for centuries, but over the past two decades, and especially over the past few years, additive manufacturing (AM) advancements have emerged that offer part designers capabilities once thought to be impossible.

.

Metal AM Basics Over the years the industry has used a flood of acronyms to describe a range of AM processes, many trademarked by equipment manufacturers. Eventually ASTM standardized the terminology through its ASTM F2792 standard. Two common forms of metal AM cited by this standard are powder bed fusion (PBF) and directed energy deposition (DED). The […]

Click here to view original web page at www.thefabricator.com

0 Comments