The conversation around 3D printing and traditional manufacturing methods like injection molding or thermoforming is often oppositional, but it’s not always a question of one versus the other.

.

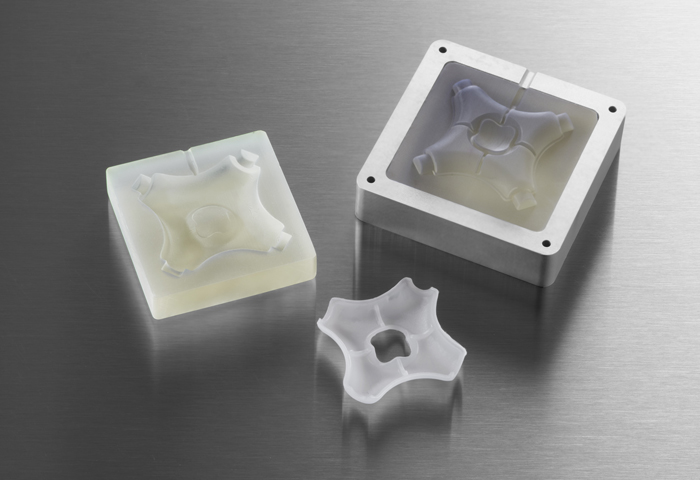

In addition to fabricating end-use products directly, 3D printing offers compelling advantages in hybrid production setups as an intermediate process alongside conventional processes. By using 3D-printed molds, dies and patterns for various molding and casting processes, you can combine the benefits of these technologies for prototyping and low-volume production. This will make the manufacturing process more time- and cost-efficient and allow for faster production.

.

This article will describe six traditional manufacturing techniques easily supplemented by stereolithography (SLA) 3D printing: injection molding, thermoforming, casting, overmolding, compression molding and silicone casting. 3D-printed injection molds in an aluminum frame with the finished injection molded part. Injection Molding With affordable desktop 3D printers, temperature-resistant 3D printing materials and benchtop injection molding machines, it is possible […]

Click here to view original web page at www.machinedesign.com

Texas Prototype is a full-service concept to production service company offering concept review, design consultancy, material selection, prototyping, and low volume production.

.

A division of Texas Injection Molding, we understand the requirements of high-volume manufacturing and offer design for manufacturing experience to ensure cost-effective manufacturable products as product designs are delivered from prototype to high volume production.

0 Comments