When surgeons replace part of a blood vessel — something they do in 450,000 patients per year in the United States to treat blood clots, coronary disease, stroke damage and more — the grafted vessel is monitored by CT scans, ultrasounds and other expensive imaging techniques.

.

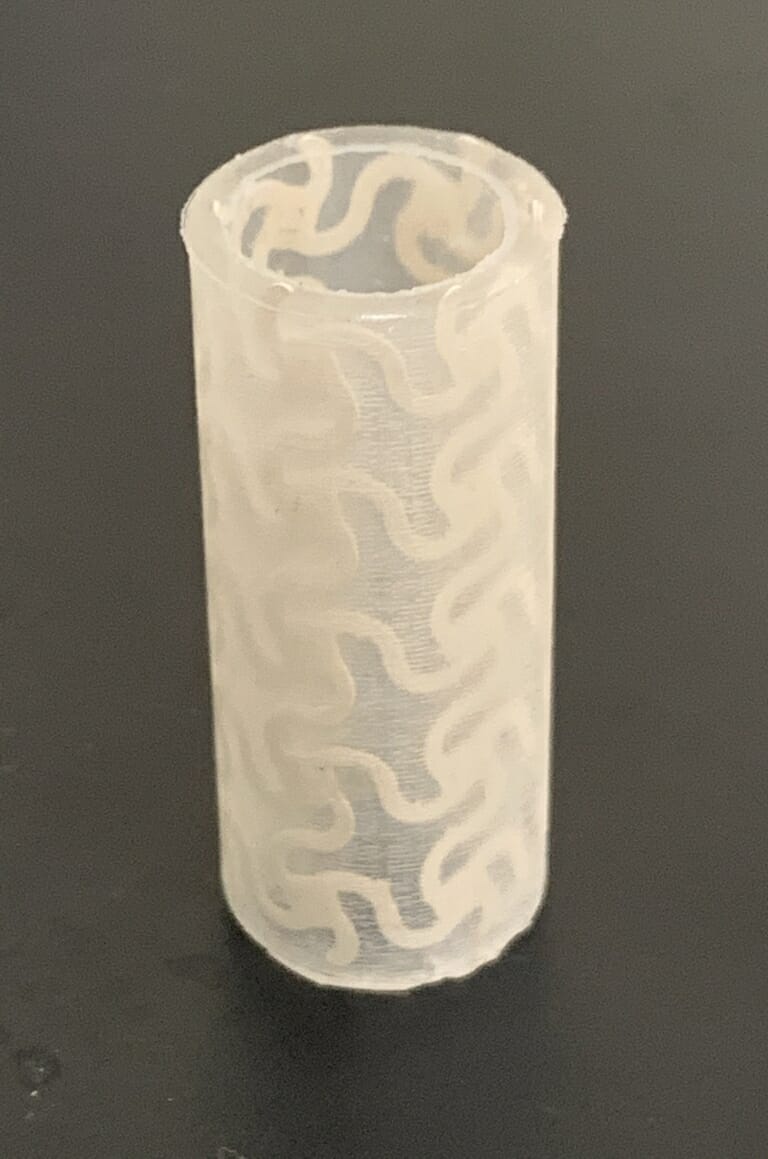

Despite all that effort, between 40% and 50% of those grafts fail. The implantable, 3D-printed artificial blood vessel is made of a flexible composite and capable of real-time monitoring.

.

That’s one reason University of Wisconsin–Madison materials science engineers are developing a new, 3D-printed artificial blood vessel that allows doctors and patients to keep tabs on its health remotely. The implantable vessel, made of a flexible composite and capable of real-time monitoring, is described in a new study published in the journal Advanced Functional Materials by UW–Madison professor Xudong Wang and graduate student Jun Li. “This artificial vessel can produce […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments