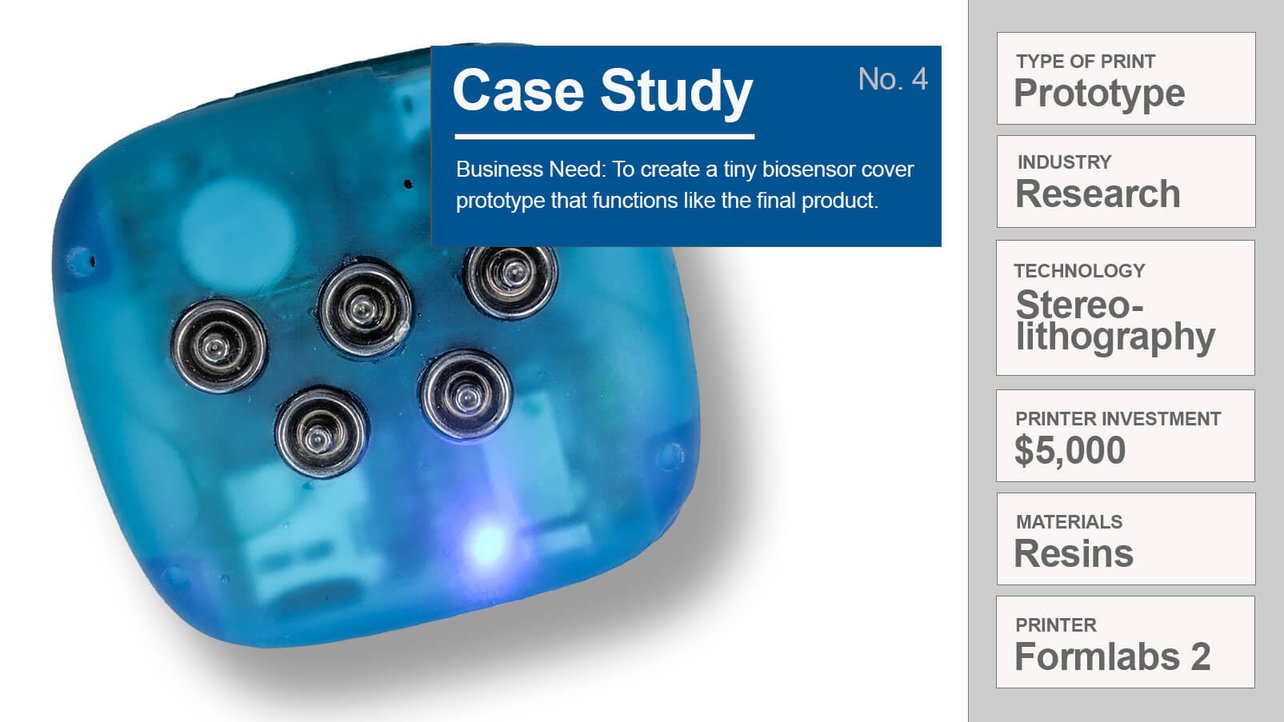

Affordable, versatile resin 3D printers let research engineers experiment on printed prototypes that look and act more like a final product.

.

When researchers at Italy’s SensibiLab were testing their latest wearable biosensor technology, comfort was critical. A big, bulky prototype wasn’t an option. They had to get their prototypes as close as possible to what they envisioned the final design would look and feel like.

.

They also needed an affordable solution; some way to get a wide variety of detailed prototype parts in materials ranging from flexible to stress-resistant. The solution they found was a 3D printer from Formlabs.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments