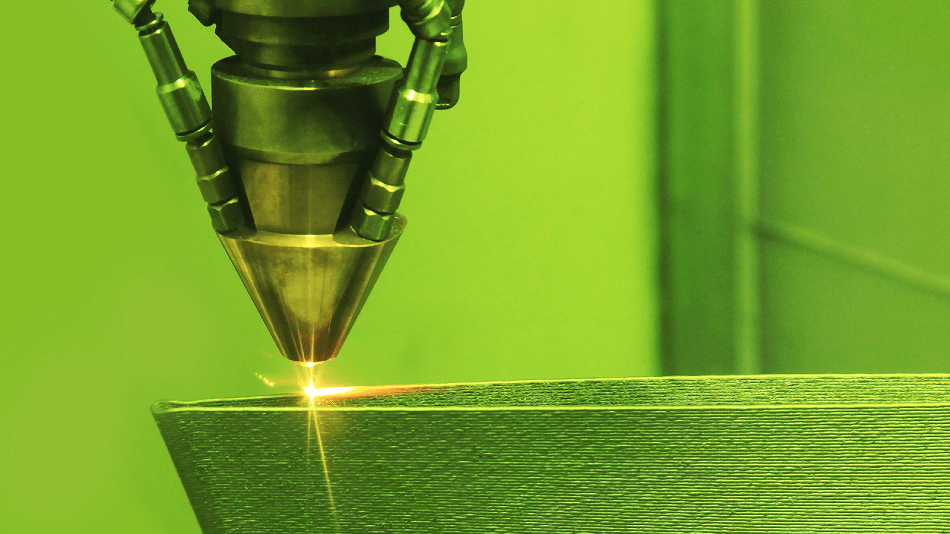

Additive manufacturing can produce parts with intricate shapes and minimal waste, offering excellent potential to redefine the development of metallic components. When 3D printing metallic parts, Argonne scientists found a correlation between temperatures at the surface and defects that form below.

.

But that potential is restricted by one crucial challenge: managing the defects during the procedure can affect the performance of 3D-printed materials. A recent article published in the Additive Manufacturing journal has now revealed a potential breakthrough solution: temperature data can be used during production to estimate the formation of subsurface flaws, so that they can be tackled immediately.

.

A research team from the Argonne National Laboratory of the U.S. Department of Energy, along with a collaborator, who is currently at Texas A&M University, has identified the possibility. Ultimately you would be able to print something and collect temperature data at the source and you […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments