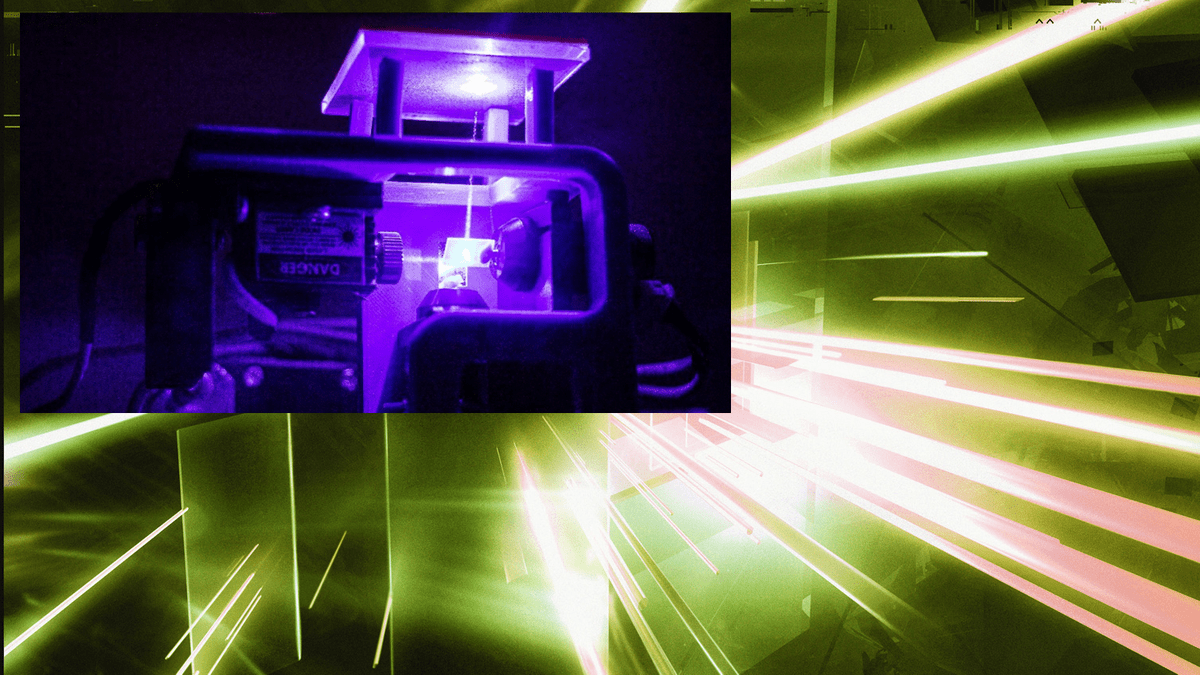

A research team at Columbia University’s School of Engineering did a little out-of-the-box thinking and turned the laser upside down inside an SLS 3D printer so that it points up. The team also replaced the conventional tray of powder material with a borosilicate glass plate.

.

.

To make a test part, the researchers put down a measured amount of polymer powder on top of the glass pane. A substrate is pressed down on top of it, then a blue laser traces out the top layer or slice of the part being created. The laser fuses the powder into a solid layer and it attaches itself to the substrate. When that layer is complete and sufficiently cooled, the substrate is lifted, bringing with it the newly created layer, and some more powder is placed on the glass. The substrate is put back on top of the glass and powder, then a […]

Click here to view original web page at www.machinedesign.com

0 Comments