Efficient electronics supply chains deal with demands such as an iPhone requiring components from suppliers in over 40 countries. The production volume throughout the supply chain is usually based on sales predictions. If demand remains as expected, this works well, with little waste, smoothly as a Swiss watch.

.

However, if there is a sudden slight consumer change in tastes or requirements, if sales of a new product are a lot better or worse than expected, or if a particular part is needed unexpectedly in a remote location or at very short notice, existing supply chains become a lot less efficient. These changes result in unused components pile-up, new components cannot be supplied quickly enough to meet demand and potentially delays an entire production run.

.

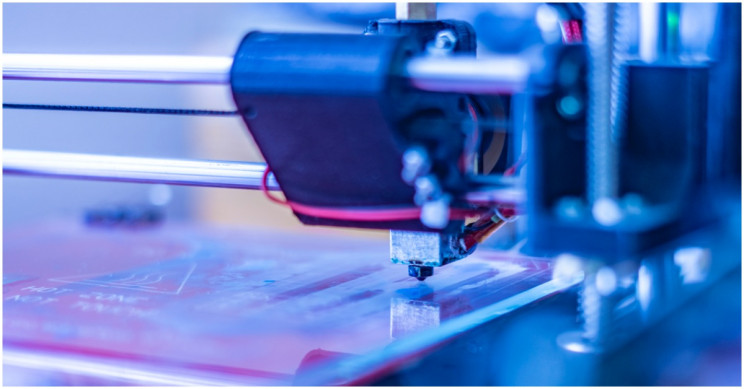

Logically, costs rise, and ultimately the potential purchaser ends up being disappointed. The solution? On-demand manufacturing. On-demand […]

Click here to view original web page at interestingengineering.com

0 Comments