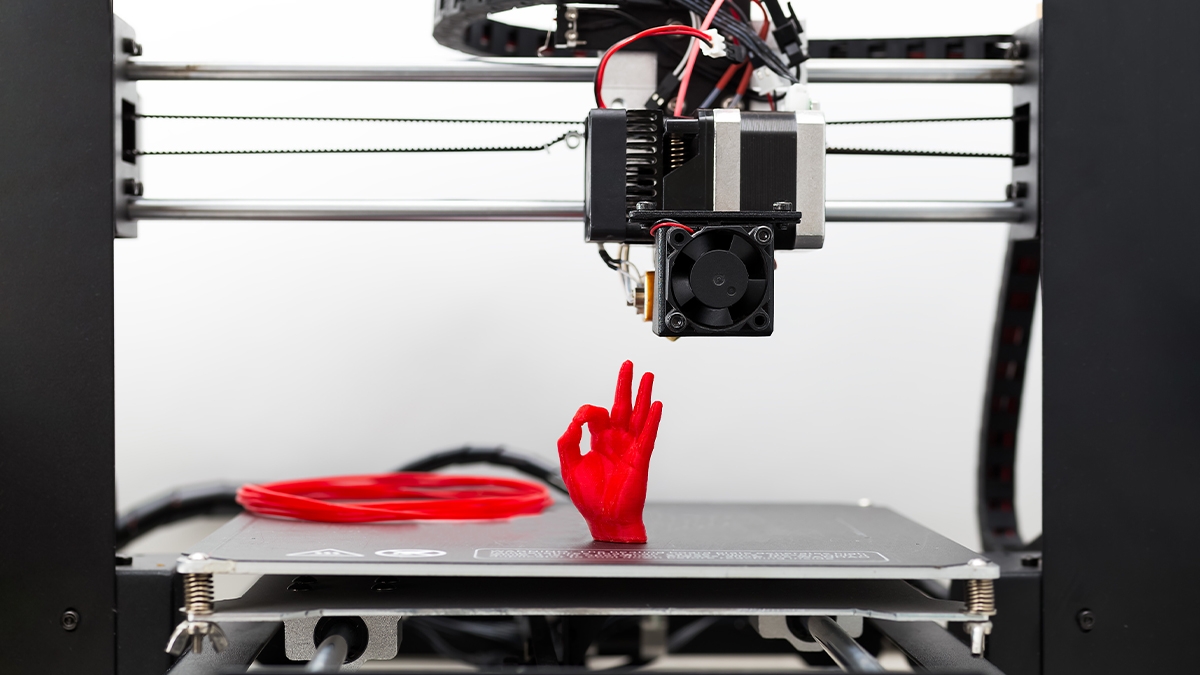

With 3D-printing technologies increasingly becoming a mainstay in modern manufacturing operations, original equipment manufacturers (OEMs), software houses, 3D-printing factories, and contract manufacturers are striving to fine-tune the efficiency and repeatability of these production methods.

.

Variability in the 3D printing of products has been a major concern of management for decades. Production engineers and managers pay special attention to product consistency with respect to dimensional accuracy and material properties such as porosity, strength, temperature, and chemical resistance.

.

Current levels of consistency in 3D printing — also known as “additive manufacturing” — are sufficient for many products. They include molds, toys, dental devices, optical lenses, eyewear, printed circuit boards (PCBs), some antennae and sensors, and non-weight-bearing metal and plastic spare parts for locomotives, heavy industrial equipment, airplanes, and military equipment. However, that is still a relatively small portion of the potential market where this manufacturing technology could be applied […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments