Researchers from the University of Chinese Academy of Sciences have published a paper in Nature Communications describing an interesting take on continuous digital light processing (cDLP) 3D printing techniques.

.

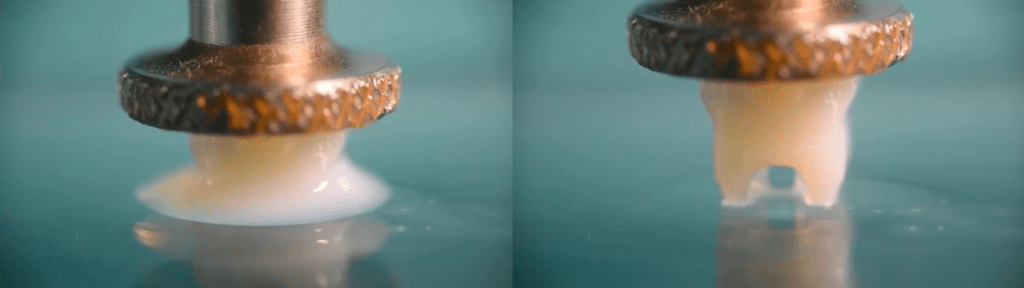

While the technique is able to 3D print in a layerless fashion like other cDLP methods, it does so using only a single drop of photopolymer resin. Noting that an excess of resin is employed to 3D print objects via cDLP, the authors set out to devise a more materially efficient 3D printing process.

.

The team pointed out that in cDLP, as well as traditional DLP and stereolithography, residual resin remains on printed parts, thus necessitating a washing step. Unnecessary resin used to fill the vat or that sticks to the final part not only results in wasted material, but it also limits print resolution and increases the cost. Inspired by lotus and pitcher plants that collect and drip spheres […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments