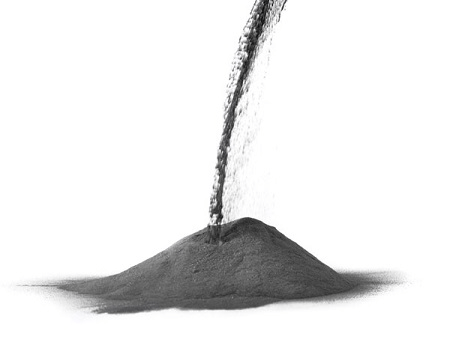

The additive manufacturing (AM) industry is still debating how best to specify virgin powders for printing and robustly assess the impact of recycling, a commercial imperative. Ideally, analysis alone should be sufficient to determine with reasonable certainty whether a powder will process efficiently and whether the resulting part will meet performance targets. The reality is that print trials are essential but optimizing testing is crucial, for the development of new materials, to confirm consistency in the supply chain, and to establish effective recycling strategies.

.

Such optimization relies on identifying measurable properties that both robustly differentiate materials and correlate with critical properties of the printed part. In an article with TCT Magazine, Jamie Clayton (Operations Director at Freeman Technology) examines the value of multi-faceted bulk powder characterization within this context, referencing recent work by researchers at the National Center for Additive Manufacturing Excellence, Auburn University. Click here to read ‘ […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments