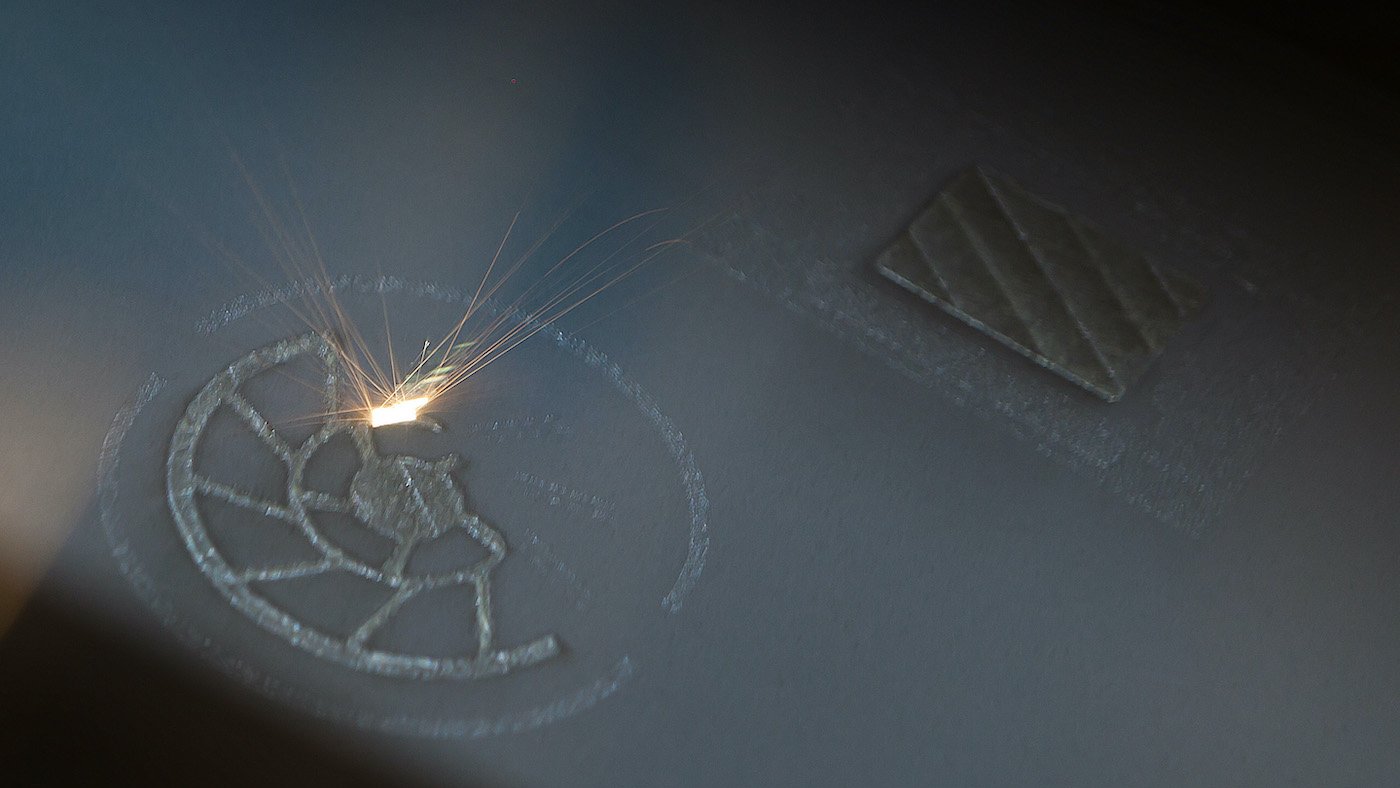

Baker Hughes metal powder AM Florence, Talamone, Celle, Aberdeen, Houston, Kariwa and Dhahran. These are the seven locations in which Baker Hughes has deployed additive manufacturing centres of excellence.

.

Just seven years ago, it had none. While 2020 has seen the company harness its additive capability to address medical device and PPE shortages as a result of the COVID-19 pandemic, 2019 was a year of significance, for it qualified as many end-use additively manufactured components as the previous five combined. Baker Hughes now has a collection of more than 450 qualified parts which, altogether, have been additively manufactured over 25,000 times. “Without question,” Dr. Mikhail Gladkikh, the company’s Global Technology and Operations Leader for the Additive Services Growth Venture, says, “we are the leader in the area for oil and gas on functional additive manufacturing applications.” That industry leadership, exhibited through its myriad downhole and turbo machinery applications, stems […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments