Five years ago, Detroit auto show crowds scratched their heads over a car whose body, frame and interior emerged fully formed at the show from computer printers that laid down layers of carbon-fiber infused plastic to form the three-dimensional components.

.

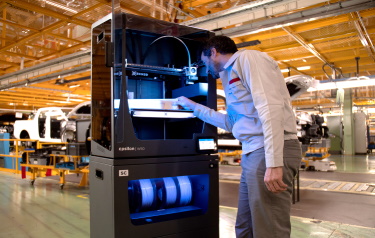

The 3D printing of auto parts, demonstrated then by a small company called Local Motors, has accelerated from auto show curiosity to manufacturing necessity in just a few short years. This year, printed parts logged 80,000 miles on Chevrolet’s Corvette, IndyCar, NASCAR and Silverado race teams, while providing prototype duty on production vehicles like the Ford Mustang GT500. 300×250 image ad With its hand-made cars and focus on immediate results, the racing industry is the current focus of 3D-printed parts, but manufacturers don’t rule them out for production-line vehicles. “We’re on a journey of identifying opportunities across a number of areas including motorsports, product development and future production vehicles,” […]

Click here to view original web page at www.hastingstribune.com

0 Comments