Manufacturing has been revolutionised by technology. However, pharmaceutical manufacturers are only just beginning to see the potential of innovative product creation.

.

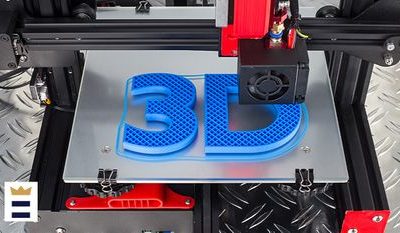

The potential benefits of technology in healthcare are vast, and revolutionary techniques are clearing the way for a cost-effective, efficient and tailored approach to medicinal production. One study from the LSE suggests that the cost of bringing a new drug to market is upwards of US$985 million. This is then reflected in the cost paid by insurance companies and end-users. The need to accelerate technology to drive these costs down is essential, and innovation is key. Here we look at the technology which is allowing pharmaceutical manufacturing to be revolutionised. While medicine is no stranger to the marvel of 3D printing, pharmaceutical manufacturing is yet to hop on the trend. 3D-printed teeth and prosthetics are already commonly used in the health industry to assist patients. However, there is a distinct lack of approved 3D-printed pharma products in the US marketplace. Medicines can be produced through 3D printing. This has interesting benefits, including unique tailoring to a specific patient’s needs. In 2015, the US FDA approved the first medicine that had been produced by 3D printing. The precision of […]

Click here to view original web page at www.engineerlive.com

0 Comments