BOSTON, Dec. 15, 2020 /PRNewswire/ — Although 3D printing as a technology has been around for several decades, it has made serious headway into factories, homes, and offices since the patents for the fused deposition modeling (FDM) printing process expired in 2009.

.

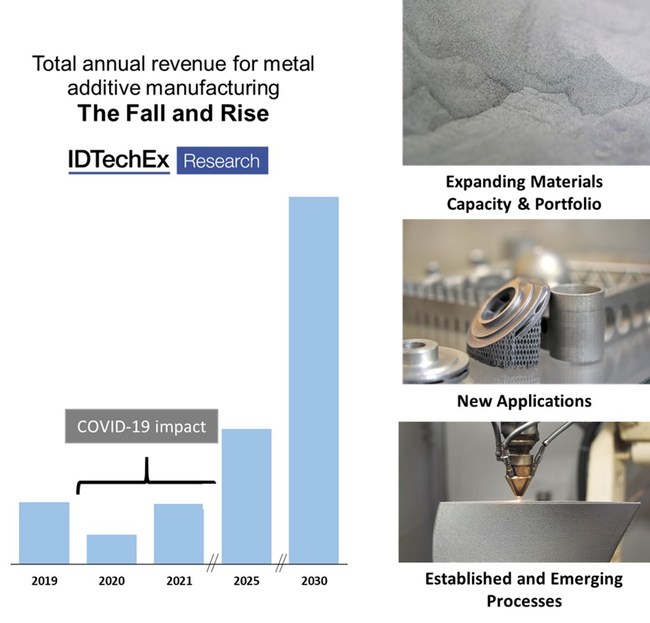

In the years have that followed, 3D modeling has become increasingly popular – in homes for hobbyists and in industry, particularly for prototyping and the early phases of product development. But in 2020, the landscape began to change once more. Continue Reading Total annual revenue for metal additive manufacturing. Source: IDTechEx (PRNewsfoto/IDTechEx) Although the COVID-19 pandemic has interrupted the 3D printing sector and its end users (such as printing bureaus), new directions of travel have nonetheless emerged. Some opportunities have even been directly prompted by the pandemic. 3D printing and the fight against COVID-19 In late 2019/early 2020, health systems in much of the world went onto a war footing as the COVID-19 pandemic took hold. Demand for PPE and medical peripherals like filters and swabs went through the roof, but 3D printing was well placed to respond – and it did. Italian company Isinnova developed a 3D-printed connector, the Charlotte valve , which could be used […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments