Global supply chains have felt the impact of the pandemic for quite some time and continue to face challenges navigating the disruption of production lines even as more regions of the world and business centers gradually re-open and bring more personnel back on-site. The biggest challenge that will remain for the foreseeable future is the shortage of semiconductors, and the signs have been there for months.

.

Last December, Volkswagen said that semiconductor bottlenecks meant it would produce 100,000 fewer cars in the first quarter of 2021, as its parts makers were unable to secure supplies. Nissan, Renault, Daimler and General Motors are also struggling with the shortage, which may lead to production being reduced by as much as 20% per week. In February, the unexpected snowstorms that hit Texas also significantly impacted the supply chains supporting semiconductor production, causing even more delays. New manufacturing lines are required for semiconductor fabrication plants, otherwise known as fabs, to increase capacity. A key challenge has been that the semiconductor capital equipment manufacturers helping to enable fabs in meeting the demand are unable to pivot their own product development cycles and production to meet the increased need. They are challenged by their reliance […]

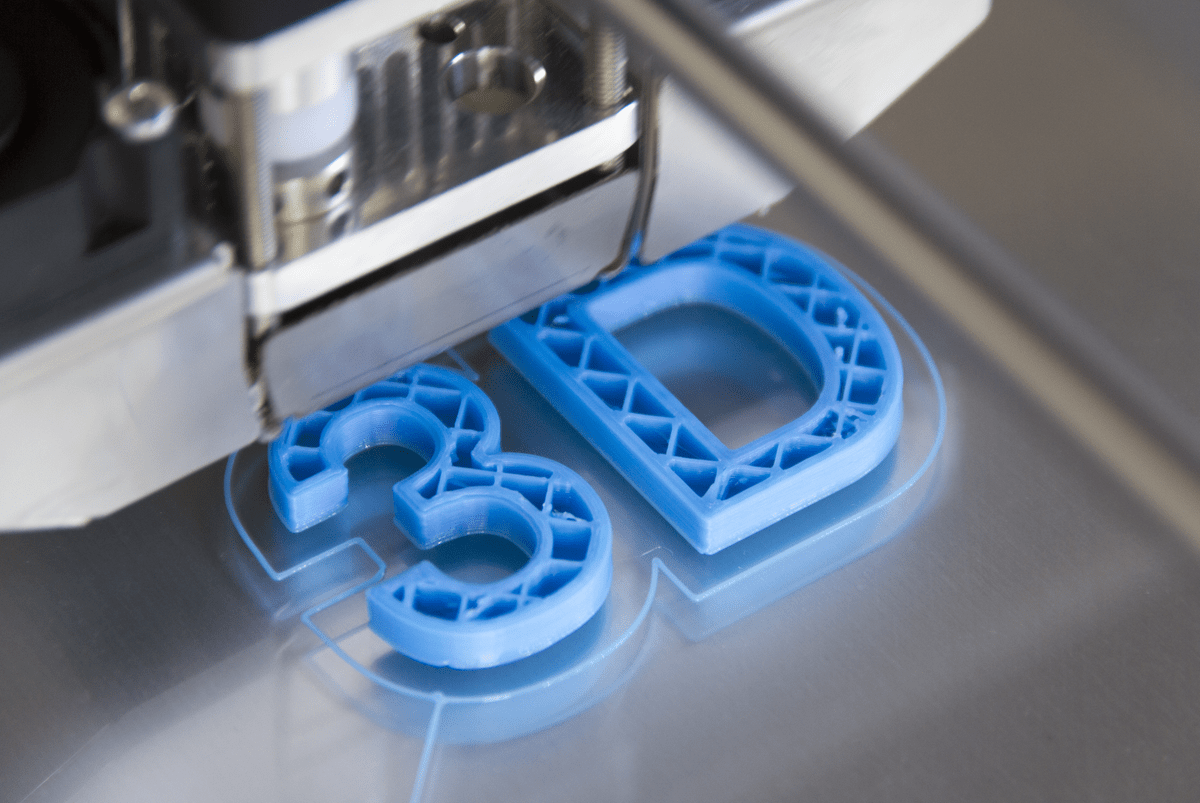

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments