3D-printable gels with improved and highly controlled properties can be created by merging micro- and nano-sized networks of the same materials harnessed from seaweed, according to new research from North Carolina State University.

.

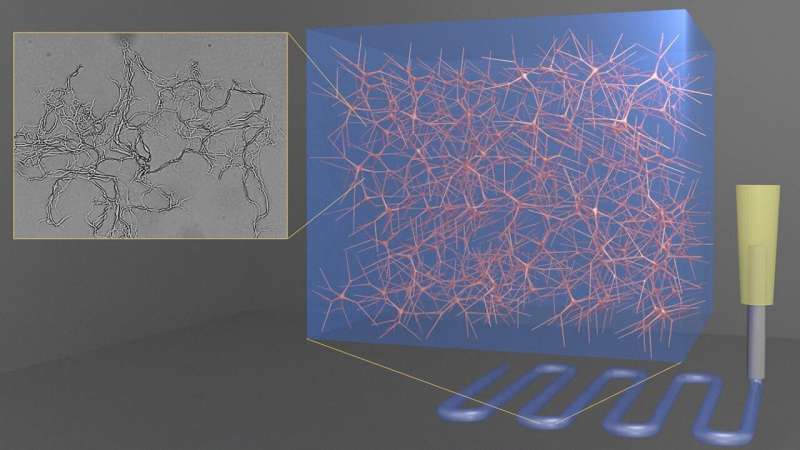

The findings could have applications in biomedical materials—think of biological scaffolds for growing cells—and soft robotics. Described in the journal Nature Communications , the findings show that these water-based gels—called homocomposite hydrogels—are both strong and flexible. They are composed of alginates— chemical compounds found in seaweed and algae that are commonly used as thickening agents and in wound dressings. Merging different-size scale networks of the same alginate together eliminates the fragility that can sometimes occur when differing materials are merged together in a hydrogel, says Orlin Velev, S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at NC State and corresponding author of the paper. “Water-based materials can be soft and brittle,” he said. “But these homocomposite materials—soft fibrillar alginate particles inside a medium of alginate—are really two hydrogels in one: one is a particle hydrogel and one is a molecular hydrogel. Merged together they produce a jelly-like material […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments