Welding 3D-printed components with a laser is the goal of scientists at the Institut für Integrierte Produktion Hannover (IPH) and the Laser Zentrum Hannover e.V. (LZH). In the new research project ‘QualLa’, they want to develop an expert system that supports small and medium-sized enterprises in optimizing additive manufacturing processes – so that the printed components can subsequently be welded soundly with the laser.

.

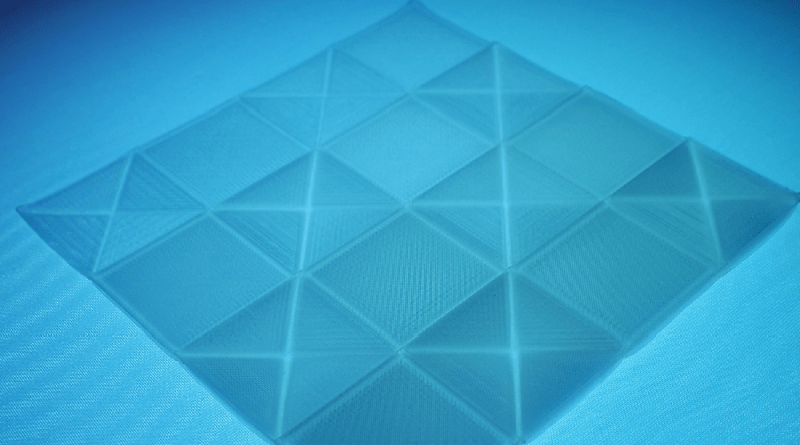

For injection-molded plastic components, laser transmission welding is already an established industrial joining process. For components from the 3D printer, however, the joining does not yet work because cavities and boundary layers in the 3D-printed components prevent a uniform weld. These cavities and boundary layers are individual to each component because, in additive manufacturing, no two components are alike. Even components from the same series are only identical on the outside; the internal structure can be different. To enable small and medium-sized enterprises (SMEs) to weld 3D-printed plastic components with lasers without analyzing each component in detail in advance, the IPH and LZH scientists want to develop an expert system and bundle process knowledge in this computer program. In the project ‘ Quality assurance in laser welding of additively manufactured thermoplastic components (QualLa)’ , researchers […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments