The demand for flexible wearable electronics has spiked with the dramatic growth of smart devices that can exchange data with other devices over the internet with embedded sensors, software, and other technologies. Researchers consequently have focused on exploring flexible energy storage devices, such as flexible supercapacitators (FSCs), that are lightweight and safe and easily integrate with other devices.

.

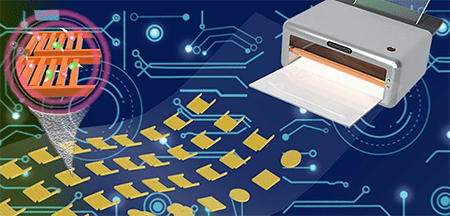

FSCs have high power density and fast charge and discharge rates. Printing electronics, manufacturing electronics devices and systems by using conventional printing techniques, has proved to be an economical, simple, and scalable strategy for fabricating FSCs. Traditional micromanufacturing techniques can be expensive and complex. In Applied Physics Reviews ( “Printed flexible supercapacitor: Ink formulation, printable electrode materials and applications” ), by AIP Publishing, researchers from Wuhan University and Hunan University provide a review of printed FSCs in terms of their ability to formulate functional inks, design printable electrodes, and integrate functions with other electronic devices. The printed flexible supercapacitor with customized patterns. (Image: Wei Wu’s group) Printed FSCs are generally manufactured by printing the functional inks on traditional organic and inorganic electrode materials on flexible substrates. Due to the thin film structure, these printed devices can be […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments