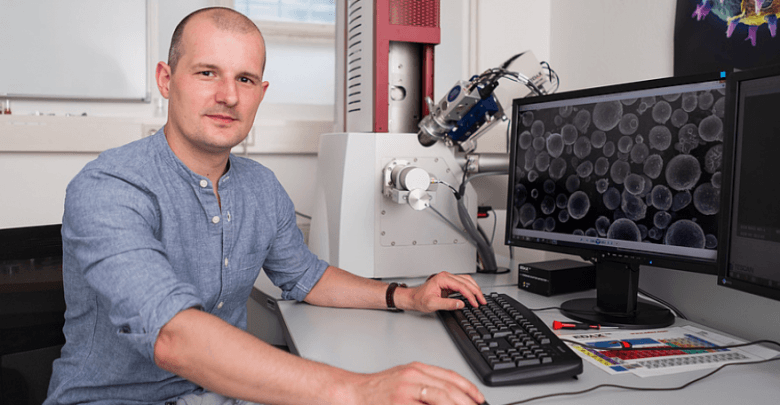

Mateusz Skalon (Photo: Hoflehner , TU Graz | IMAT)

A researcher at TU Graz in Austria has developed a new steel powder for additive manufacturing that has the potential to simplify the production of complex parts. The material, which is modified for stability, can enable manufacturers to drastically reduce production costs and material waste while exploiting new levels of design freedom.

Within the metal AM market, stainless steel is an important material with a range of applications. According to estimates cited by TU Graz , the use of stainless steel powder in AM is increasing by over 30% every year. Still, certain challenges remain when working with steel powders, especially when using selective laser melting or similar additive technologies. In these processes, the component is built up, layer by layer, using a laser. Throughout the process, however, it is often necessary to integrate support structures into the part to […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments