You might be surprised, but sand 3D printers go back to the late ‘90s! Generis and MIT are responsible for this huge development. But how exactly does this technology work? At what stage is it after 20 years of research and improvements?

Today, we will focus on the innovations of sand 3D printers! Are you ready? How does a sand 3D printer work? Sand 3D printer, like all other printers, works with layers. It uses sand alike materials such as ceramics, metal particles and also silica sand. The technology used for those machines is called Binder Jetting and is widely used with different materials, for example, Stainless Steel 316 . Binder Jetting printers spread a layer of the material and then bind it with an agent, which solidifies the particles. A layer for sand 3D printer is 140-200 micrometers. When it comes to sand 3D printers, they do not […]

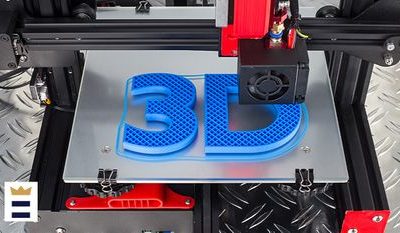

Creality Sermoon D1 review: An industrial-level 3D printer for under $700

Welcome to ZDNet's DIY-IT project lab, where I'm testing 3D printers for your entertainment and edification. Today,...

0 Comments