Since the Industrial Revolution, manufacturing technologies have never stopped evolving.

Businesses are always looking for ways to create products faster, cheaper, or with better quality.

In the past few decades, some of the most reliable processes for manufacturing custom parts fall into either of two umbrellas: additive manufacturing or subtractive manufacturing.

From their names alone, it’s easy enough to infer how additive and subtractive manufacturing technologies differ on a fundamental level. That they are two sides of the same coin is as apt a metaphor as any we can come up with.

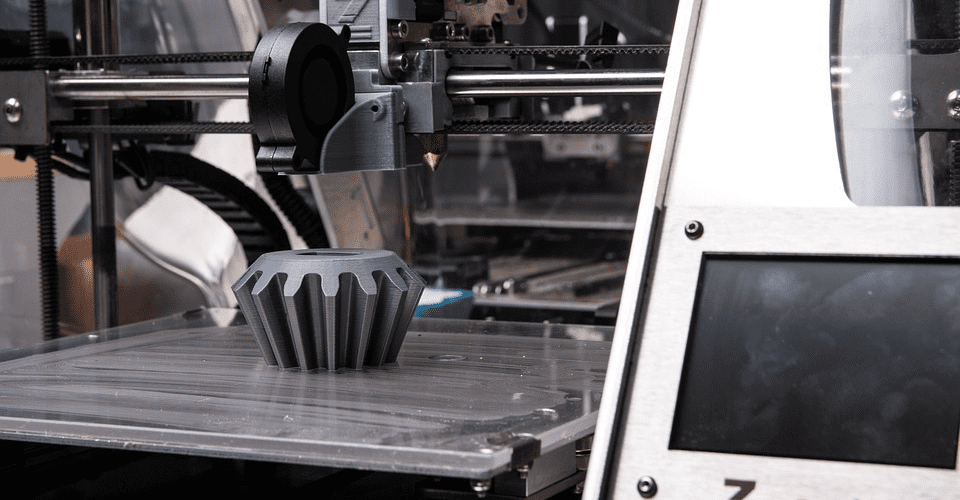

What is it about these processes that have made them so popular? Are there applications that are more appropriate for one or the other? Additive manufacturing An additive manufacturing process creates the product from the ground up layer by layer. As with most modern manufacturing processes, additive manufacturing starts with a 3D model, typically created in CAD […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments