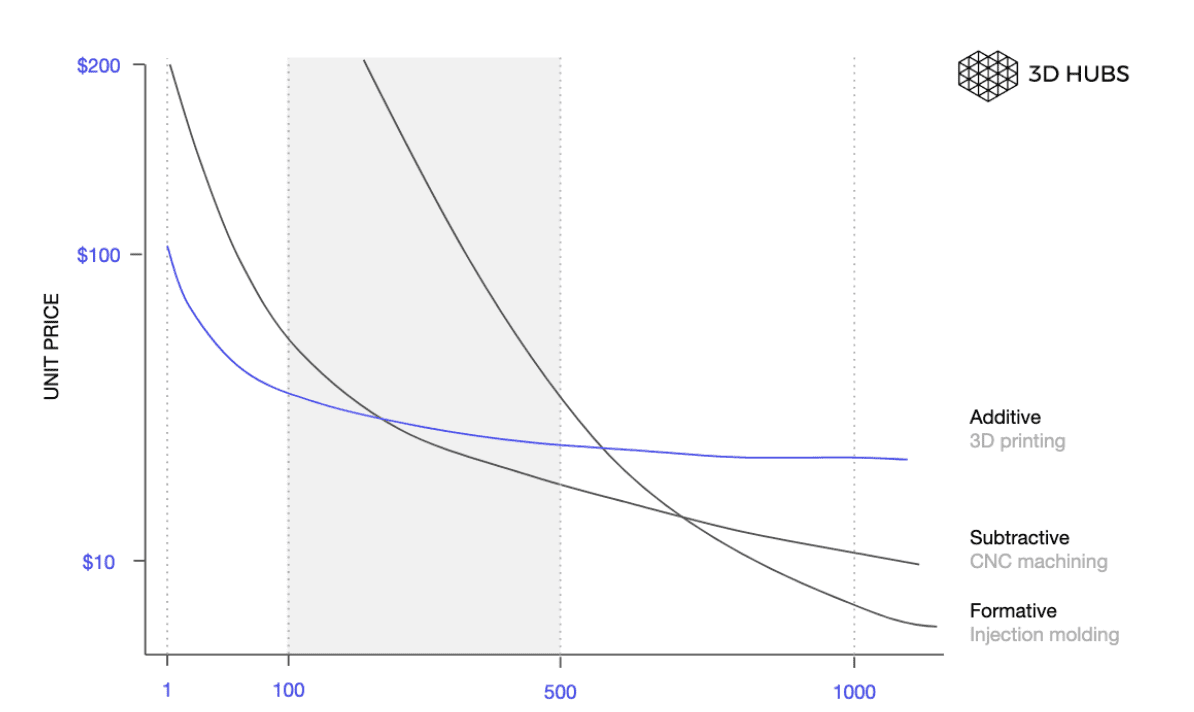

The best-use cases for 3D printing aren’t always obvious. When designing an object for additive manufacturing, it’s important to keep the limits and benefits of the process in mind. These tips will help any designer get the most out of a 3D printing service. Tip 1. Don’t Use Existing Designs Each part should be designed with an intended manufacturing process in mind. Many designers and engineers are surprised to realize that existing part designs are not always cheaper to produce with 3D printing, even at low volumes or as one off’s. As an example, consider an existing part that has been designed for CNC machining. 100 units of this part need to be produced and the desired material is SS 304L, which is available in 3D printing via DMLS and SLM. When this part is produced with CNC machining, the production cost is $35 per part. But if the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments