As 3D printing and electronics continue to advance—along with robotics—soft actuators are becoming a great subject of study, as thesis student Hong Fai Lau outlines in the recently published, ‘ 3D-Printed Inflatable Actuators – Design and Development of Soft Actuators for a Pneumatically-Actuated Soft Robotic Arm .’

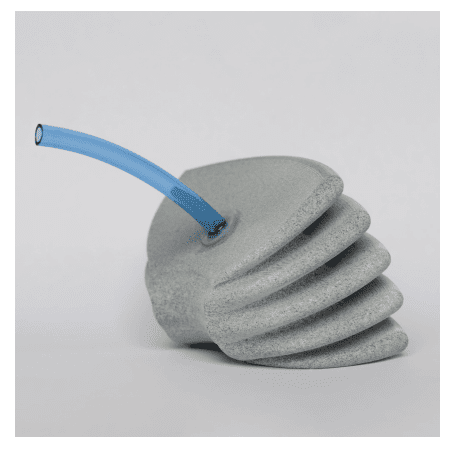

Studying the design process, but also parameters and interdependencies, Hong Fai Lau experiments with 3D printing inflatable actuators for the eventual possibility of using them in a robotic arm integrating two degrees of freedom.

Hong Fai Lau realizes there is a serious shift happening with the advent of soft actuators, and more specifically, those that are inflatable: “In a typical actuator made from rigid materials, for example, a Series Elastic Actuator or a Variable Stiffness Actuator, the schematics, components, and control together define the function of the device. In a soft inflatable actuator, however, its function solely depends on its mechanical design.” […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments