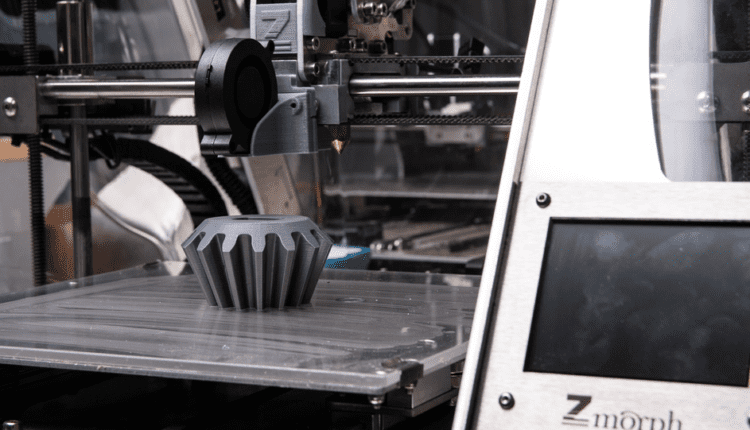

The design world seemed to open up to vast creative ideas when the 3D printer became a reality. Think up a part and print it out. The modern age was upon the world. Businesses began to put 3DP into their budgets, but some costs were a bit confusing.

It’s critical to understand when a 3D printing service is cost-effective.

Explore the top-three factors to consider before sending out a design. 1. Infill Amounts 3D printing is cost-effective when engineers can manipulate infill amounts on a given part. A classic example of infill manipulation is found in chocolate bunnies produced in the springtime. Consumers find solid bunnies, but for the most part, the products are all hollow. This production strategy lowers the bunny’s cost while still offering a quality product. Online 3D printing uses this same concept. Engineers might change their infill amounts from 50 or 60 percent to around […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments