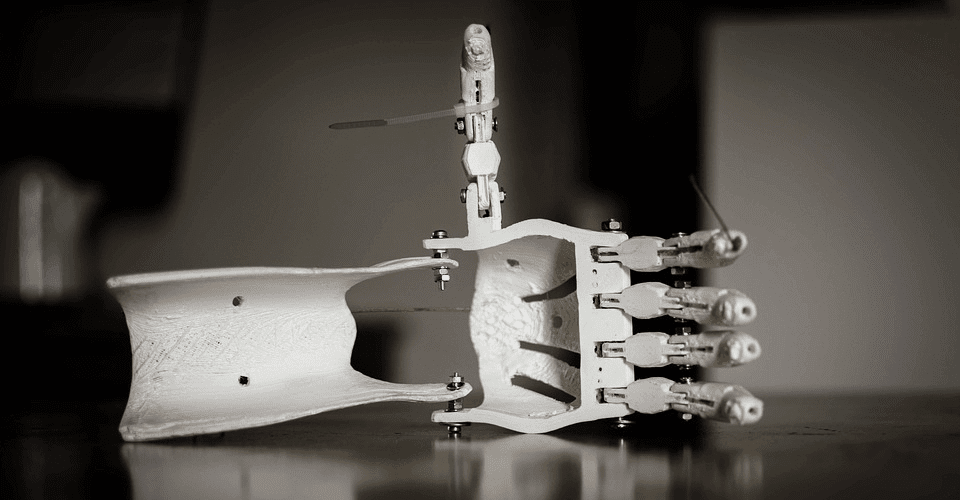

Despite the fact that 3D printing is one of the most versatile additive manufacturing technologies available today, it still has several limitations.

.

Yes, you can create just about anything on a 3D printer – given that it fits on a build platform and that your 3D printer can handle your filament material. The good news is that there are a couple of ways that you can work around these limitations.

.

Among experienced users of 3D printers, a favorite practice is to break down a model into separate interlocking parts. What’s the point of going through this complexity? Are there any best practices to ensure that your interlocking parts fit securely and snugly? Why make a design with interlocking parts? To be honest, breaking down your model into separate, smaller parts and designing interlocking joints for each of them does make your design a bit more complex. It also takes […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments