In the recently published ‘ Life Cycle Assessment of 3D Printing Geo-polymer Concrete: An Ex-ante Study ,’ authors Yue Yao, Mingming Hu, Francesco Di Maio, and Stefano Cucurachi examine the development of geo-polymers in concrete, and delve further into the use of 3D printing within the construction industry.

.

With the environment in mind, the authors are assessing the efficacy of using 3D printing and geo-polymers to replace conventional manufacturing methods with conventional materials like Portland cement.

.

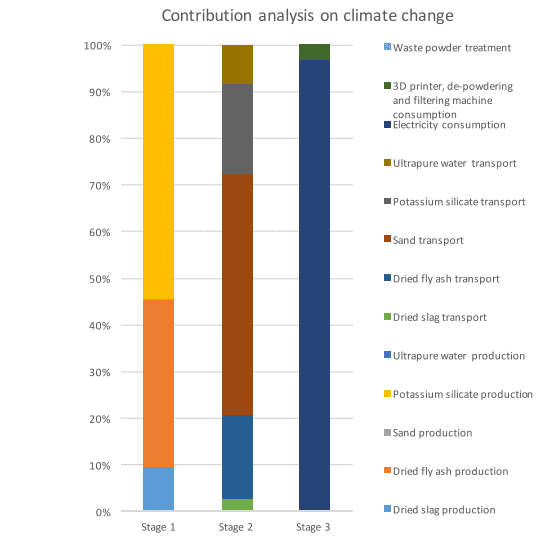

Environmental performance was evaluated through an ex-ante life cycle assessment (LCA), with manufacturer data used to pinpoint items for improvement and ‘scaled-up scenarios’ created in partnership with the company as the researchers looked into areas for improvement.

.

Waste reduction is high on the list of benefits in terms of 3D printing in construction and with cement, and while geo-polymer could have even higher environmental impacts than ordinary concrete, the study shows that with multiple improvements, it could reduce the carbon footprint. The researchers were able to achieve this by lowering the amount of silicate in geo-polymer ‘recipes.’

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments