In the recently published ‘ Fiber-reinforced lightweight foamed concrete panels suitable for 3D printing applications ,’ the authors present us with experimental results regarding a set of fiber-reinforced innovative lightweight panels (FRIL-panels) with a thickness of 12mm, created with a ‘peculiar’ foamed concrete featuring both high viscosity and cohesion.

.

While environmentally friendly solutions are sought after in many industries today, that is especially so within the 3D printing realm; however, it is difficult to have it all, and often it is hard to bring together both suitable mechanical properties and performance. Foamed concrete may be one of the answers as air bubbles act as a replacement for conventional cement, producing a more lightweight material—and reducing waste, ultimately. Microstructural air-voids are also extremely beneficial in comparison to concrete. The ‘cementitious matrix’ also includes good thermal insulation, acoustic absorption, and fire resistance.

.

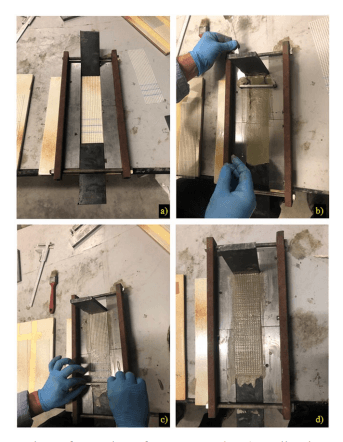

Lightweight foamed concrete (LWFC) can be used to create foundation slabs, act as filler, and can also bolster soil. The authors point out that it is handy for precast too as LWFC can be used to create blocks and panels that can be ceilings, walls, and infills. The authors have created an extrudable LWFC (E-LWFC) that allows for better optimization and does not require formworks—improving expediency in production.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments