3D Printing has had a massive impact on the car world. Low-volume manufacturers like Koenigsegg and Bugatti use it to make beautifully designed bespoke parts. Wheel designers like HRE use it to make intricate designs come to life. Classic departments at automakers like Porsche use it to recreate rare parts for restorations.

.

The tuner scene hasn’t been left out of the action, either. High-quality 3D-printed aftermarket parts have exploded in popularity in recent years.

.

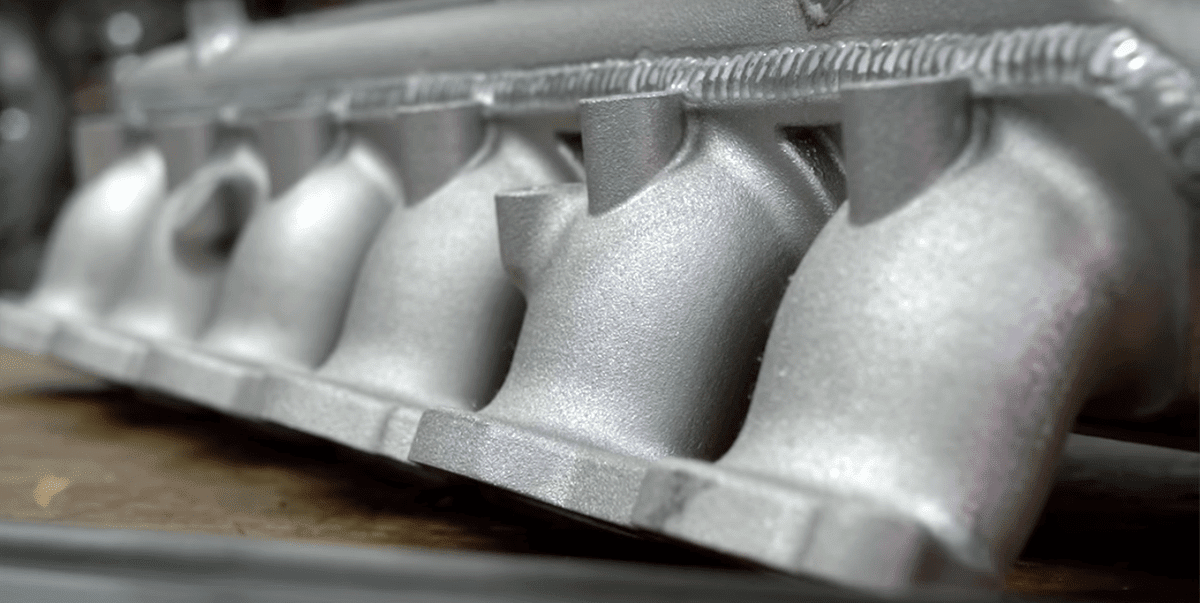

Stephan Papadakis of Papadakis Racing needed a custom intake manifold for his 1000-horsepower 2020 Supra engine build, so he decided to get one 3D-printed. He went to the manufacturing facility to document the entire process, and it’s fascinating.

.

The printer puts down layer after layer of aluminum powder, laser-welding them together as they’re placed. Parts too big to be printed in one go are printed in pieces, then later welded together. […]

Click here to view original web page at www.roadandtrack.com

0 Comments