International researchers study different features that affect binder jetting, outlining their findings in the recently published ‘ The Effect of Print Speed on Surface Roughness and Density Uniformity of Parts Produced Using Binder Jet 3D Printing .’

.

Binder jetting continues to be popular with industrial users because it is fast ; however, that does not mean prints come out perfect, leaving the scientists here to work on methods for improving the overall outcomes of prototypes and parts.

.

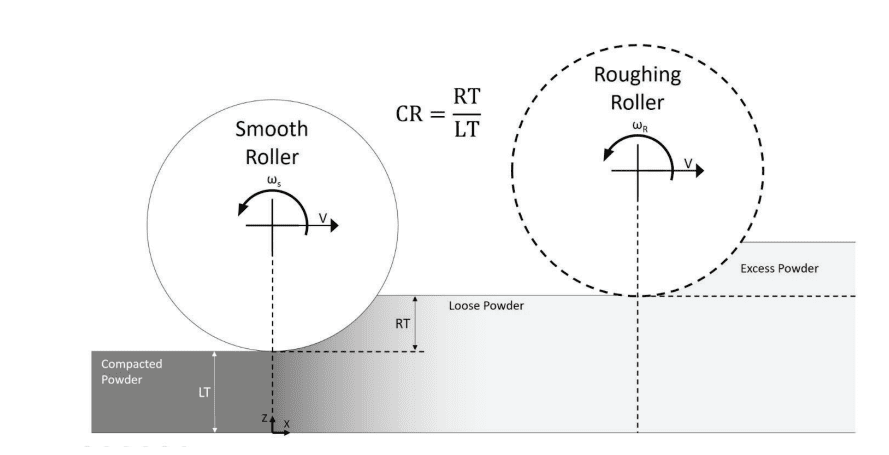

Fabrication of a binder jetting part relies on: Powder dispensing Powder spreading Binder dispensing Binder drying “The printing time (the time it takes to dispense binder droplets) can be decreased by either increasing the number of printing modules in the machine itself, or by increasing the speed at which the printhead traverses across the bed. However, increasing the printhead traverse speed can negatively affect the feature resolution and dimensional accuracy.” Consistency is […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments