Now that we’ve covered most of the notable hybrid manufacturing names in the space, both large and small, it would be helpful to know what this technology is even good for. As discussed in part one , the goal of hybrid systems is to combine the advantages of additive and subtractive manufacturing, resulting in an unbeatable method of production.

.

Here, we’ll see how those capabilities find themselves deployed in the real world.

.

Molds and Tools

.

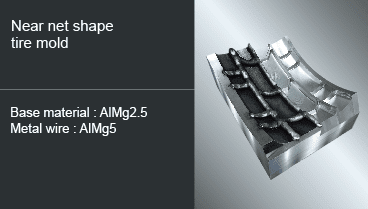

A widespread application for hybrid manufacturing currently in use today is the fabrication of metal molds and tooling. Mazak has demonstrated the use of its hybrid systems to create near-net shape tire molds beginning with a billet of A5052 aluminum alloy before additively depositing A5356 aluminum to completion. Matsuura customer Owen Greenings & Mumford Ltd. Used a LUMEX Avance-25 to fabricate mold tool inserts featuring […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments