Polypropylene, or PP, is one of the most common polymers that you’ll find around the house. It’s great for its translucency as well as its resistance against chemicals and fatigue. Being both food- and microwave-safe, it’s often used in household plastic containers.

.

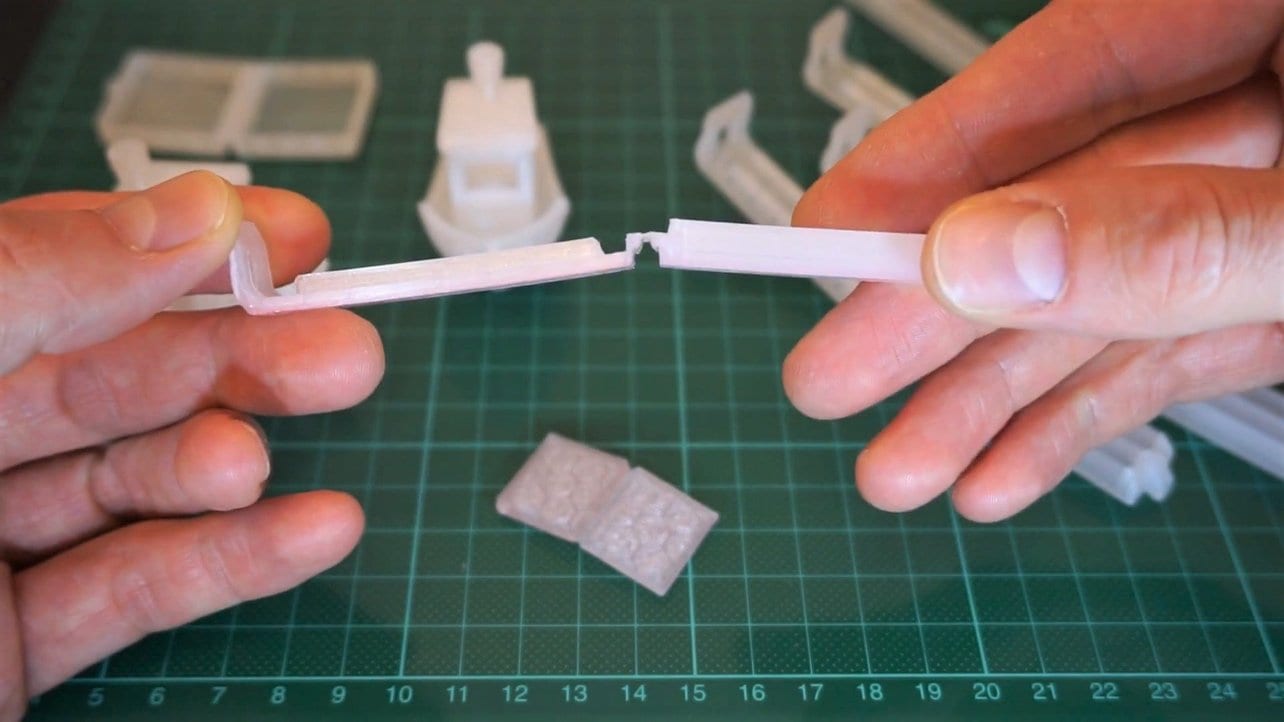

For 3D printing, PP is great for anything that needs to be light, water-tight, or durable. Case hinges, for example, represent a very popular use, as PP can bend repeatedly without breaking.

.

While PP’s excellent durability makes it an appealing material to print, it is notoriously difficult to handle. Let’s take a look at the material’s challenges as well as a few ways to get around them.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments