VELO3D and its SupportFree additive manufacturing process help KW Micro Power turn a radically different design concept into reality.

.

After numerous no-bids by various service bureaus and metal additive equipment manufacturers, KW Micro Power’s microturbine component design, dubbed “the spaceship” for obvious reasons, would likely never have been built without help from VELO3D.

.

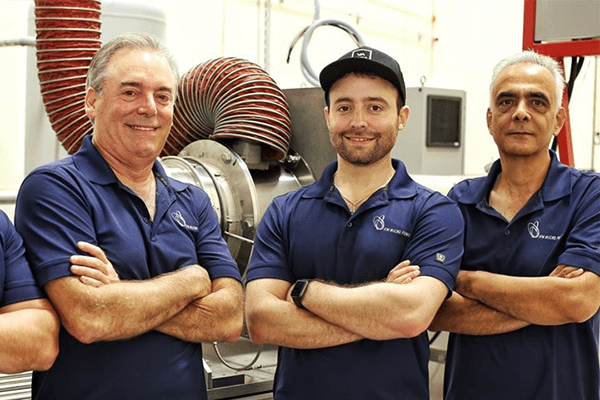

Whether it’s for the portable generator that keeps the refrigerator cold and the light bulbs lit during a power outage, or the hybrid-electric engines that can lift delivery drones high into the sky, the world needs compact and reliable energy sources. Making them smaller, more powerful, and especially more affordable is the vision of Enrique Enriquez, president of KW Micro Power. Over the past four years, Enriquez has worked tirelessly in pursuit of his company’s goal: a microturbine generator roughly the size of a microwave oven that can crank out more power than systems ten times […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments