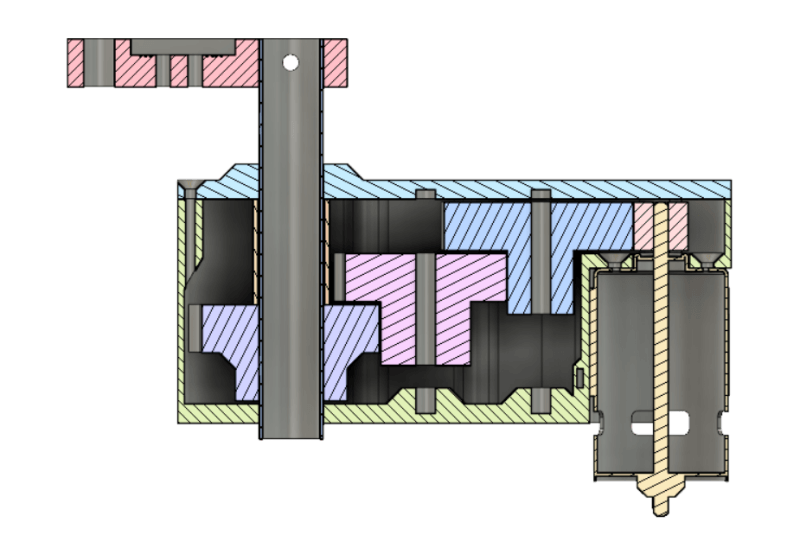

This servo/gear reduction was assembled with almost all 3D-printed parts.

.

Apart from a brushed 36 V DC-motor, a stainless steel shaft, and screws for holding the servo together, the only other non-printed part is the BTS7960B motor driver. Some interesting stats about the plastic servo – its stall torque is about 55 kg/cm, reaching a peak current draw of 18 A when using a 6s LiPo battery outputting 22-24 V.

.

The shaft rotates using two 20 mm holes and lubrication. (Ball bearings were originally in the design, but they didn’t arrive on time for the assembly.) The holes of the gears are 6.2 mm in diameter in order to fit around the shaft, although some care is taken to sand or fill the opening depending on the quality of the 3D print.

.

This isn’t [Brian Brocken]’s only attempt at 3D-printing gears. He’s also built several crawling robots, a turntable […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments