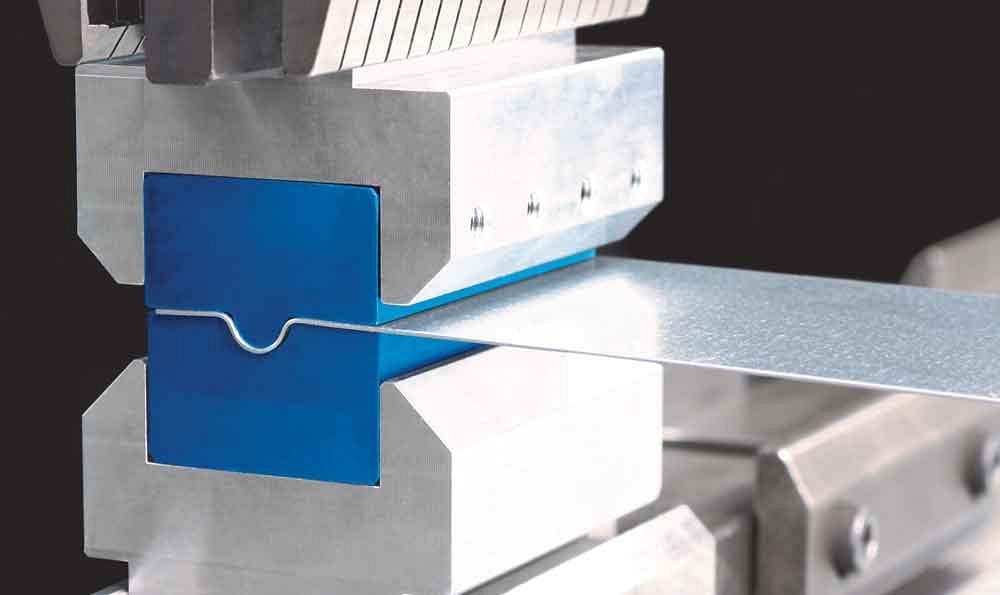

Small, low-tonnage press brakes are making a comeback, and 3D-printed tools could make these machines more flexible than they already are.

.

Small, light-tonnage press brakes, often electric or a hydraulic-electric hybrid, are undergoing a resurgence of popularity. Years ago shops might have strayed from them, considering their low tonnage and short bed lengths. After all, in a job shop, why invest in a machine that can process only small parts, while longer-bed machines can form just about whatever you throw at them? Fiber lasers have taken cutting capacity to another level, and now shops need to do the same for forming.

.

Offline programming and simulation can create a complicated stage-bend program in minutes, meaning an intricate part can be formed with tools spanning across the bed. Because programming is essentially automatic, these bed-spanning setups make sense even for short runs. Considering all this, […]

Click here to view original web page at www.thefabricator.com

0 Comments