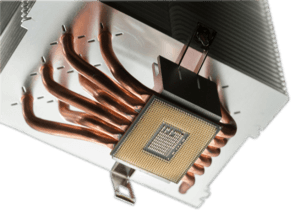

Cooling elements for power electronics, lighting, etc. are traditionally extrusion parts. In the early days and for low power applications, these cooling elements where sufficient enough. Modern power electronics have a higher power density and heat dissipation. There is a need for more efficient heat exchangers that can evacuate more heat in a smaller space.

.

If the internal channels and fins are optimised for heat extraction, they are so complex that 3D printing is the only manufacturing technique possible. However, current metal 3D printing techniques are too expensive and too slow for series production.

.

Making metal 3D printing affordable by a disruptive patent pending technology

.

‘Economic and ecological competitive metal 3D printing on serial production scale’. This is the ambitious mission of ValCUN, a Belgian technology startup established in 2016. Co-founders Jonas Galle […]

Click here to view original web page at www.elektormagazine.com

0 Comments